Modern Commercial Ice Maker Features for Bars & Cafes

Unlocking Commercial-Grade Ice Production: A Deep Dive into Modern Ice Maker Features

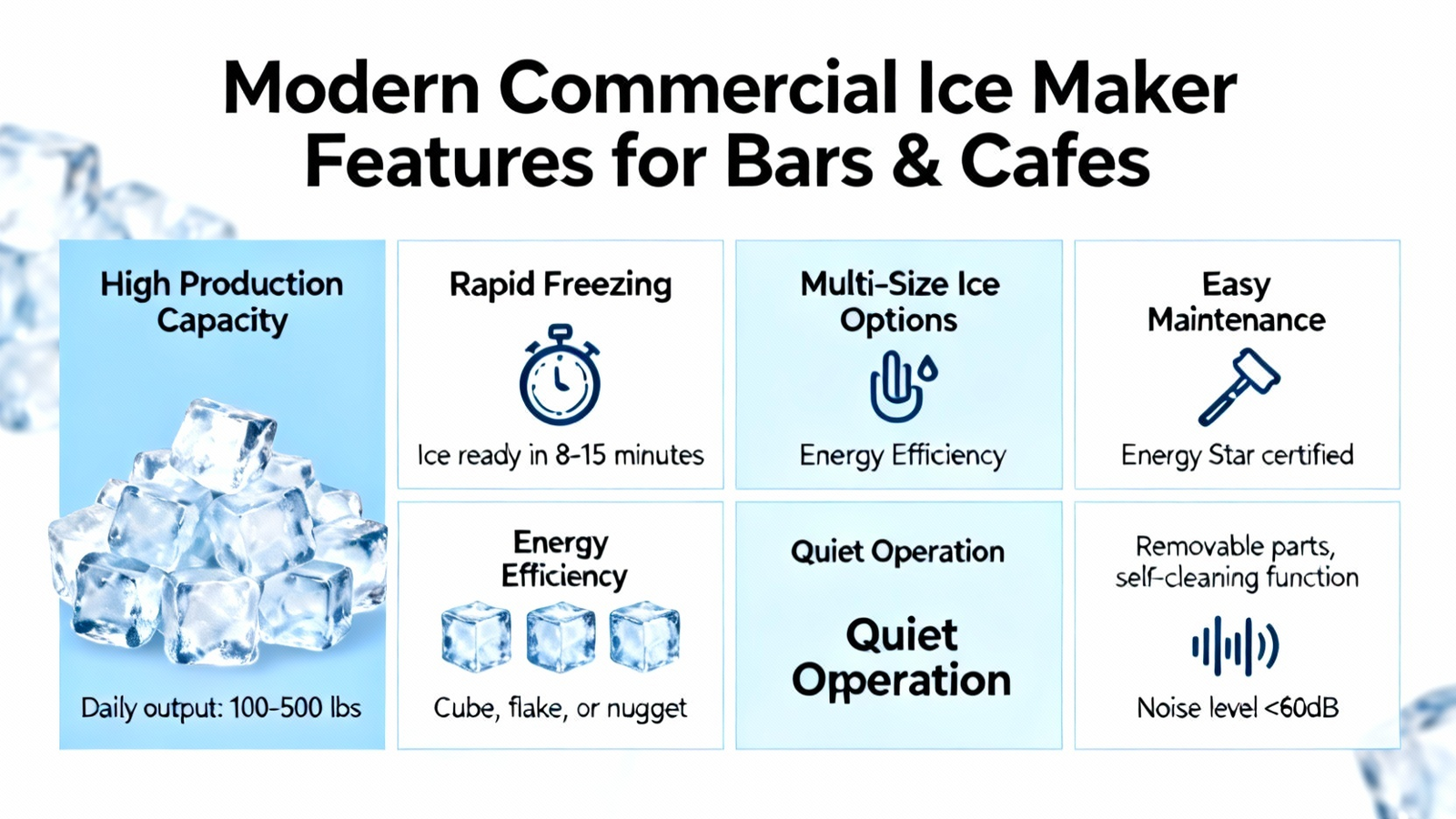

For bars, cafes, and restaurants, a reliable ice maker is a cornerstone of daily operations. Modern commercial ice machines, like the TITTLA 100Lbs/24H Commercial Ice Maker, integrate advanced filtration, automation, and durable engineering to meet high-demand needs. This article explores the critical features that define efficient commercial ice production, from water quality to operational design, ensuring you understand what drives performance and hygiene in a foodservice setting.

The Critical Role of Water Filtration in Ice Quality

Superior ice begins with superior water. A high-efficiency water filter is not an accessory but a necessity for any commercial ice maker. It directly impacts taste, clarity, and equipment longevity. Tap water contains minerals like calcium and chlorine, which can affect ice taste and cause scale buildup inside the machine, reducing efficiency over time. As noted in discussions on water treatment, scale inhibition is a primary function of filtration to protect appliances (Wikipedia, Water filter). An integrated filter system, such as the one designed for simple connection in the TITTLA machine, converts tap water into purified water, ensuring each ice cube is clean-tasting and the machine’s internal components are protected from impurities that can hinder performance.

Automation and Hygiene: The Self-Cleaning Advantage

Operational simplicity and consistent hygiene are paramount in busy commercial environments. Modern units address this with fully automated cycles. Features like automatic self-cleaning and defrosting, controlled via an intuitive LCD panel, remove the guesswork and labor from maintenance. This is crucial for food safety. As highlighted in food service equipment discussions on Reddit, regular cleaning is vital to prevent mold and bacterial growth, which can occur in the damp interiors of neglected machines (Reddit, r/KitchenConfidential, December 2022). The auto-clean function ensures the water channels and ice-making components are sanitized regularly, maintaining ice purity and machine reliability with minimal manual intervention.

Engineering for Durability and High-Volume Output

Commercial-grade engineering is defined by robust materials and powerful performance. A stainless steel exterior, as used in the stainless steel ice maker, provides a hygienic, corrosion-resistant surface that withstands rigorous cleaning and a demanding kitchen environment. At the heart of performance is a powerful compressor. For instance, a 495W compressor enabling the production of 100 pounds of ice in 24 hours meets the high-volume needs of peak service times. This aligns with commercial requirements where downtime is not an option. The design often includes practical elements like a front observation window with interior lighting for easy monitoring and removable components for thorough cleaning, ensuring the machine is built for both output and ongoing usability.

Optimizing Installation and Workflow Integration

The final measure of a commercial appliance is how seamlessly it integrates into an existing workspace. A freestanding ice maker with clear specifications for water line and drain hookup simplifies installation. Inclusion of essential accessories—like drain pipes to efficiently remove wastewater and dedicated ice scoops to maintain hygiene—shows thoughtful design for real-world use. As emphasized in food service forums, using a dedicated scoop, rather than a glass, prevents contamination and glass breakage in the ice bin (Reddit, r/bartenders, February 2023). Furthermore, a substantial storage bin (e.g., 24 lbs) with thick insulation extends ice holding time, while the machine’s footprint and built-in mobility features ensure it fits logically into the workflow of a bar, cafe, or restaurant kitchen.

In conclusion, selecting a commercial ice maker requires a holistic look beyond simple output numbers. It demands attention to the foundational element of water filtration, which guarantees ice quality and machine health. Automation for cleaning and operation drastically reduces labor and upholds stringent hygiene standards, a non-negotiable in the food service industry. The core engineering—powerful compressors for reliable high-volume production and durable stainless-steel construction—ensures the unit can withstand commercial demands day after day. Finally, the inclusion of practical accessories and a design conducive to easy installation allows the commercial ice maker machine to become an efficient, integrated part of your operation. By prioritizing these interconnected features, businesses can secure an ice-making solution that supports efficiency, safety, and ultimately, customer satisfaction.

This article really highlights how a modern commercial ice maker is essential for keeping a busy bar or cafe running smoothly.

\}}

This article really highlights how a modern commercial ice maker is essential for keeping a busy bar or cafe running smoothly.

\}}

This article really highlights how a modern commercial ice maker is essential for keeping a busy bar or cafe running smoothly.

\}}

This article really highlights how a modern commercial ice maker is essential for keeping a busy bar or cafe running smoothly.

\}}

This article really highlights how essential a reliable commercial ice maker is for keeping a busy bar or cafe running smoothly.

\}}