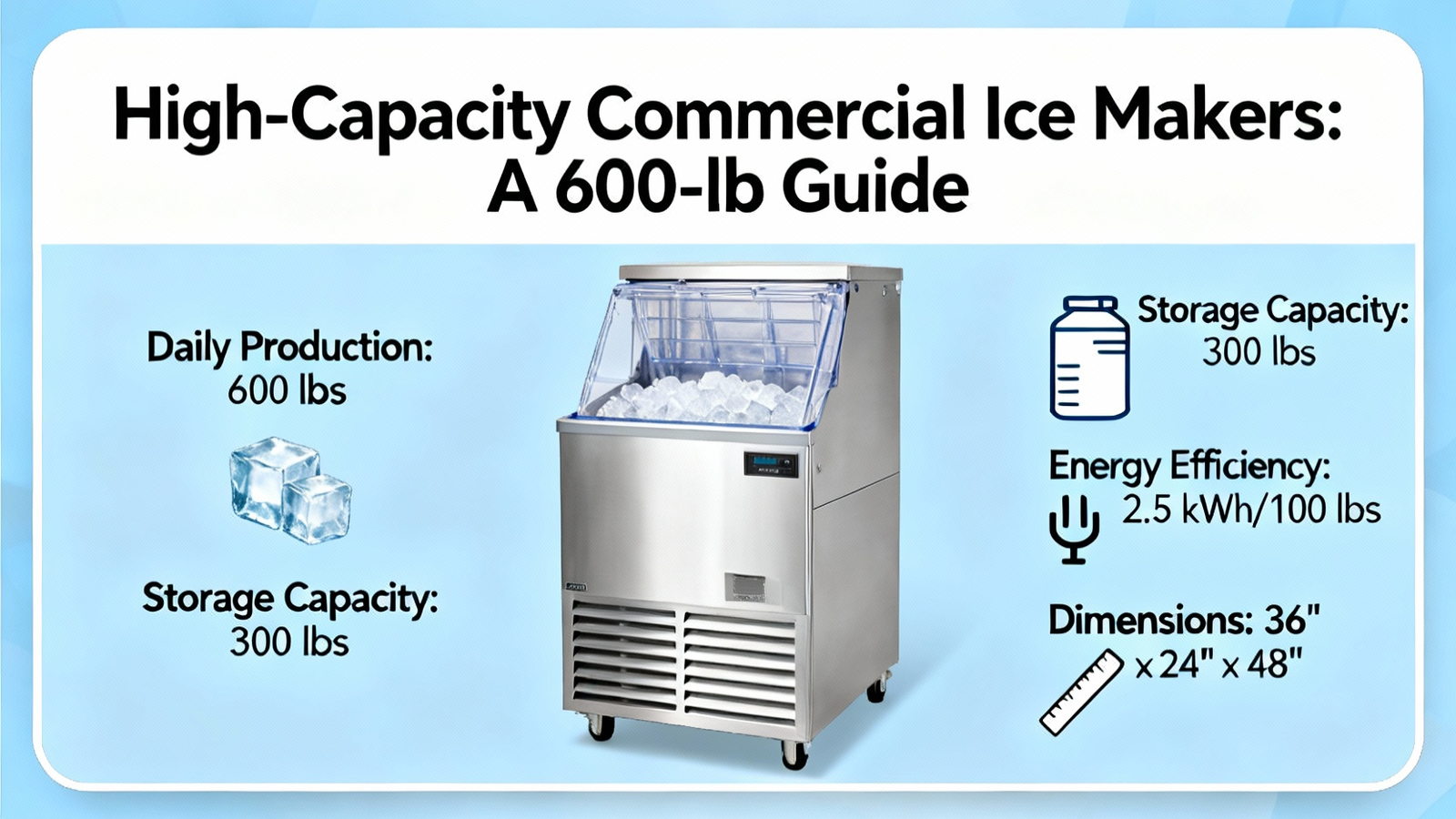

High-Capacity Commercial Ice Makers: A 600-lb Guide

In the demanding world of food service and hospitality, a reliable ice supply is non-negotiable. This article explores the critical features of high-capacity commercial ice makers, using the 182 Modular Ice Maker as a benchmark. We’ll delve into the engineering behind daily production, smart storage design, and the advanced systems that ensure hygiene and reliability, providing a comprehensive guide for your business upgrade.

Engineering for Uninterrupted High-Volume Production

At the core of any commercial operation is the need for consistent, high-volume output. A unit capable of producing 600 pounds of ice per day addresses the peak demands of busy bars, restaurants, and healthcare facilities. This capacity isn’t just a number; it’s the result of robust engineering, including a powerful compressor and fan system designed for near-continuous cycling. As noted in discussions on commercial equipment efficiency, redundancy and output capacity are primary concerns for businesses to avoid service disruption (Reddit, January 2022). This level of production ensures that even during a rush, the ice supply never becomes a bottleneck.

Smart Storage and User-Centric Design

Production is only half the equation; effective storage is equally critical. A 300-pound storage bin acts as a crucial buffer, allowing the machine to produce ice in cycles while service continues uninterrupted. User-centric features like a built-in ice scoop and an intuitive touch control panel minimize staff training time and operational friction. The touch panel, often allowing for cycle adjustments or cleaning mode initiation, represents a shift from analog buttons to more reliable, sealed interfaces that are easier to sanitize—a key consideration in modern food safety protocols.

The Critical Role of Advanced Filtration

The clarity and taste of ice are directly tied to water quality. An integrated advanced filtration system is not an optional extra but a necessity for producing crystal-clear, odor-free ice. It removes sediments, chlorine, and other impurities that can affect ice quality and, by extension, beverages. According to Wikipedia, scale buildup from mineral deposits is a leading cause of ice maker malfunction and degraded performance. A robust filtration system protects the machine’s internal components, like the water distribution system and evaporator plate, from scaling, which directly extends the equipment’s lifespan and reduces maintenance costs.

Durability and Performance Foundations

The long-term reliability of a commercial ice maker hinges on its core mechanical components. The synergy between a powerful fan and a high-grade compressor is what enables consistent thermal exchange and efficient ice formation cycle after cycle. These components are typically designed for commercial duty cycles, differing significantly from residential units. As highlighted in industry forums, investing in units with reputable compressor technology is advised for durability, as these are the heart of the cooling system and the most costly to repair or replace (Reddit, August 2023). This engineering focus ensures optimal performance under constant use.

Upgrading your ice production is a strategic investment in your business’s operational flow and customer satisfaction. As we’ve examined, the ideal solution combines massive daily production, like the 600-pound capacity, with intelligent storage to create a seamless supply. User-friendly controls streamline staff interaction, while an advanced filtration system is essential for protecting both ice purity and the machine’s intricate components from scale. Ultimately, the durability promised by a commercial-grade compressor and fan system translates to long-term reliability and lower total cost of ownership. For establishments looking to eliminate ice anxiety and elevate their service, a machine embodying these principles is key. To explore a unit that integrates these critical features, consider the 22.24 in. 600 lbs./24h Ice Tray Count 182 Stainless Steel Split Commercial Ice Maker. By prioritizing engineering, hygiene, and smart design, you secure a foundational element that keeps your customers refreshed and your operations running smoothly, day in and day out.

This guide really highlights why a high-capacity commercial ice maker is such a crucial investment for busy operations.

\}}

This guide really highlights why a high-capacity commercial ice maker is such a crucial investment for busy operations.

\}}

This guide really highlights why a high-capacity commercial ice maker is such a crucial investment for busy operations.

\}}

This guide really breaks down why a high-capacity commercial ice maker is such a crucial investment for busy operations.

\}}

This guide really breaks down why a high-capacity commercial ice maker is such a crucial investment for busy operations.

\}}

This guide really breaks down why a high-capacity commercial ice maker is such a crucial investment for busy operations.

\}}

This guide really breaks down why a high-capacity commercial ice maker is such a crucial investment for busy operations.

\}}

This guide really breaks down why a high-capacity commercial ice maker is such a crucial investment for busy operations.

\}}

This guide really breaks down what makes a 600-lb commercial ice maker like the 182 Modular so essential for high-volume operations.

\}}

This guide really breaks down what makes a 600-lb commercial ice maker like the 182 Modular so essential for high-volume operations.

\}}

This guide really breaks down what makes a 600-lb commercial ice maker like the 182 Modular so essential for high-volume operations.

\}}