Heavy-Duty Commercial Ice Makers: Specs, Safety, Setup

The Ultimate Guide to Heavy-Duty Commercial Ice Makers: Specs, Safety & Setup

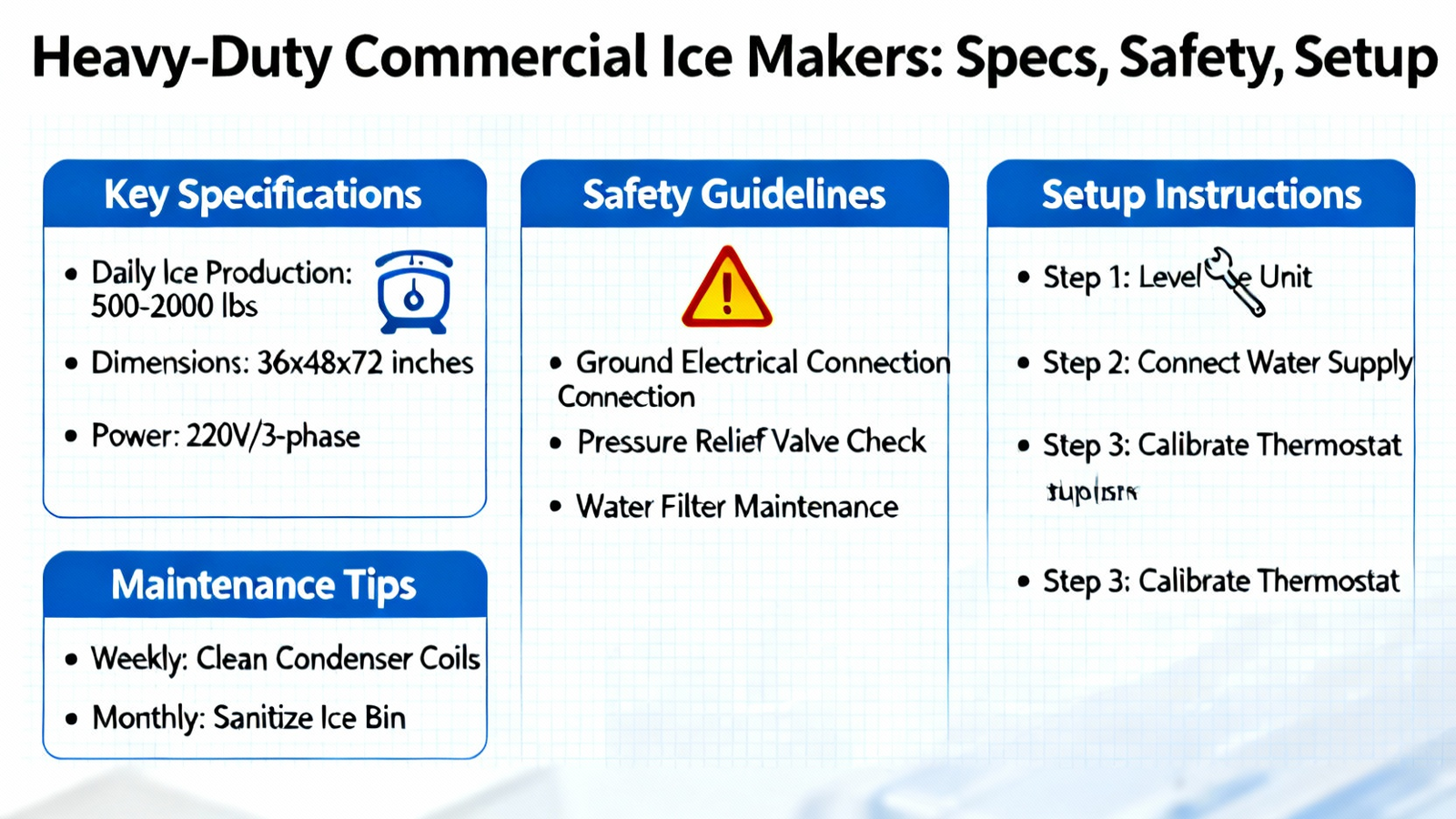

Selecting the right commercial ice maker is crucial for hospitality operations. This guide delves into the key features, essential installation requirements, and critical safety protocols for a durable, stainless steel unit designed for high-volume environments like restaurants and bars, ensuring you maximize your investment.

Engineering for Endurance and Efficiency

At the core of a reliable commercial ice maker is its construction and components. The highlighted unit features a durable stainless steel exterior, which is the industry standard for corrosion resistance, hygiene, and longevity in demanding kitchens. Its operation on standard 110V 60Hz power (780W) makes it accessible for most US commercial settings without specialized electrical work. A significant modern advancement is the use of R290 (propane) refrigerant. According to Wikipedia, R290 has a “negligible ozone depletion potential and very low global warming potential” compared to traditional hydrofluorocarbons (HFCs), making it an environmentally friendly choice that complies with evolving regulations. Its compatibility with climate types SN, N, and ST ensures reliable performance across varied US regional temperatures.

Strategic Installation for Optimal Performance

Proper installation is not just about plugging it in; it directly impacts ice production, machine lifespan, and safety. The unit’s substantial net weight of 145.51 lb and dimensions of 26.4 × 23.2 × 61.4 in necessitate a planned location. Critical steps include connecting to a potable drinking water supply with a pressure between 14.5-58 psi, as improper pressure can damage the system. A gravity-fed drain line must be installed, with its outlet lower than the ice maker’s, to handle wastewater and meltwater effectively. As emphasized in user discussions on Reddit, such as a 2023 thread on kitchen equipment maintenance, ensuring adequate clearance (at least 5.9 inches on all sides) is vital for airflow and heat dissipation, preventing overheating and efficiency loss.

Critical Safety and Operational Protocols

Adhering to safety guidelines protects your staff, property, and the equipment. The unit’s Safety Protection Type I plug and 70-inch cord are designed for grounded outlets; using an extension cord is strongly discouraged due to fire risk from overheating. Key protocols include:

- Initial Settling Period: After delivery, let the unit stand upright for 24 hours before first use to allow the refrigerant and oils to settle, as advised by manufacturers to prevent compressor damage.

- Environmental Placement: Keep the machine away from direct sunlight, stoves, or radiators. High ambient temperatures, as noted in a Reddit discussion by HVAC professionals, can significantly increase ice-making cycle times and strain the system.

- Proper Use: Only use water to make ice. Never place the unit or cord near flammable materials, and outdoor use is not recommended due to exposure and temperature control issues.

Maximizing Your Commercial Ice Investment

For operations requiring robust output, a machine like the 23.23 in. 750 lbs./24h Capacity Commercial Stainless Steel Ice Maker represents a significant investment. To ensure it delivers its promised 750 lbs./24h capacity, meticulous attention to the pre-installation checklist—water pressure, drainage, clearance, and electrical requirements—is non-negotiable. Regular cleaning and descaling, a point universally stressed by both equipment manuals and industry forums like Reddit, are essential to maintain ice quality and production speed. Choosing a unit with a stainless steel construction and modern refrigerant like R290 future-proofs your business against both wear and environmental policy shifts.

Conclusion

Integrating a heavy-duty commercial ice maker into your business is a decision that impacts daily operations, safety, and overhead. This analysis underscores that beyond the core specifications—such as the durable stainless steel build, efficient 110V operation, and eco-friendly R290 refrigerant—success hinges on disciplined installation and operation. The detailed requirements, from water pressure ranges and mandatory drainage to critical clearance for ventilation, are not mere suggestions but prerequisites for achieving the advertised output and machine longevity. Furthermore, strict adherence to safety protocols, including proper electrical connection, a mandatory settling period, and safe placement away from heat sources, mitigates risk and ensures compliance. As evidenced by discussions among industry professionals on platforms like Reddit, the environmental temperature and consistent maintenance are ongoing factors influencing performance. Ultimately, a model such as the commercial stainless steel ice maker offers the capacity and durability needed for high-demand settings, but its true value is realized only through informed, careful implementation and upkeep, securing a reliable ice supply that keeps service flowing smoothly.