Heavy-Duty Commercial Ice Maker Guide: Specs, Safety & Setup

The Ultimate Guide to Heavy-Duty Commercial Ice Makers: Durability, Safety, and Setup

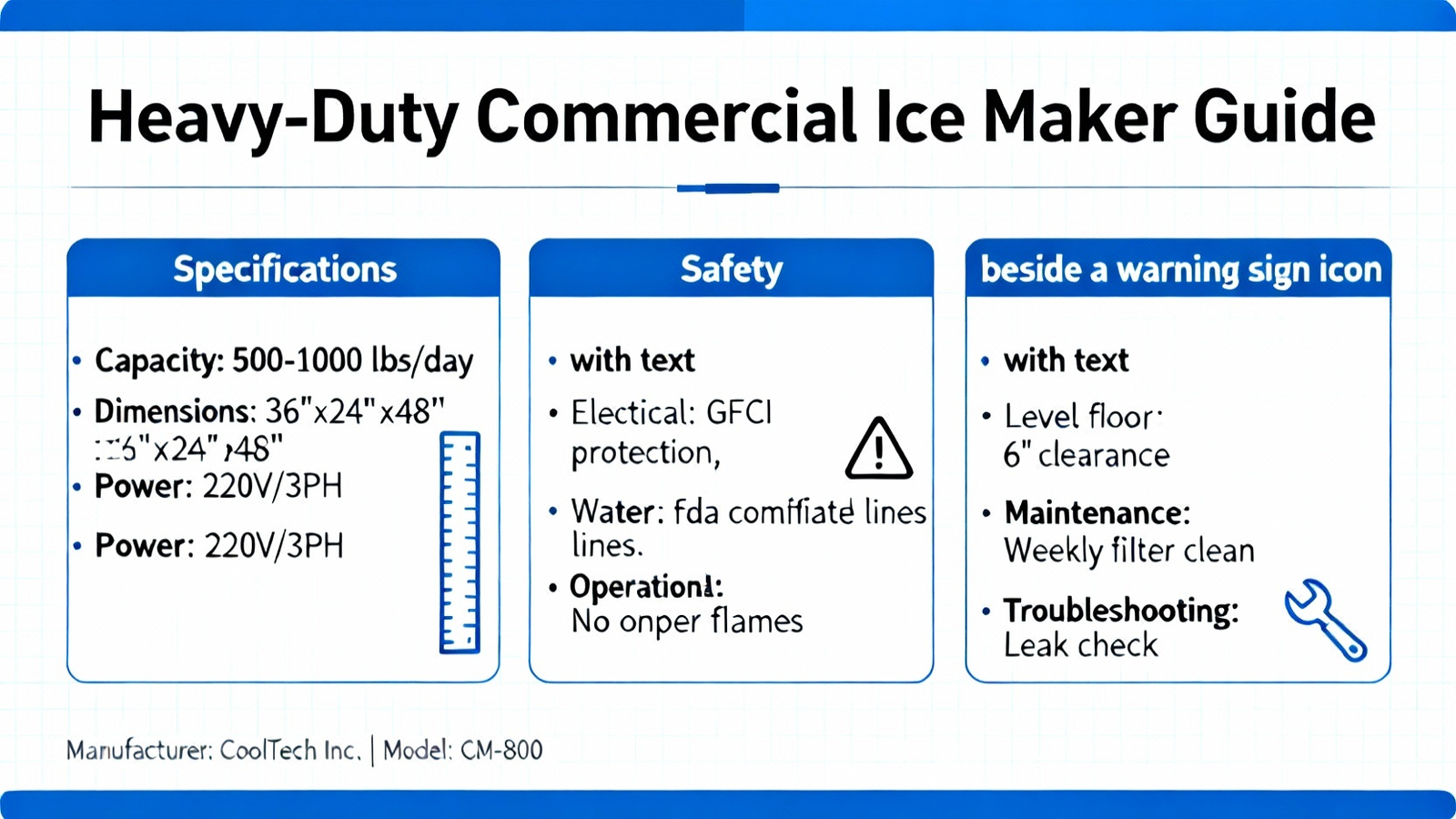

For restaurants, bars, and hotels, a reliable ice supply is non-negotiable. This guide delves into the critical features and installation requirements of a robust, stainless steel commercial ice maker designed for 110V operation. We’ll explore its durable construction, environmentally friendly R290 refrigerant, and the essential safety and setup protocols to ensure longevity and peak performance in your demanding business environment.

Engineering for the Demands of Food Service

At the core of this unit is its heavy-duty, stainless steel construction, a material chosen for its exceptional durability and ease of sanitation. Stainless steel’s resistance to corrosion and rust is paramount in commercial kitchens, where equipment is frequently cleaned and exposed to moisture. This aligns with industry-wide standards for food service equipment, as noted in discussions on commercial kitchen durability. The machine’s substantial net weight of approximately 145.51 lb signals a robust build quality designed to withstand constant use. Its compatibility with climate types SN, N, and ST ensures reliable performance across varied environmental conditions commonly found throughout the United States, from standard temperate zones to more subtropical regions.

Powering this reliability is the environmentally friendly R290 (propane) refrigerant. R290 has a significantly lower Global Warming Potential (GWP) compared to traditional hydrofluorocarbon (HFC) refrigerants. As highlighted in environmental policy discussions, the shift towards natural refrigerants like R290 is accelerating due to regulatory changes and sustainability goals. This ice maker represents a forward-thinking choice for businesses aiming to reduce their environmental footprint without compromising cooling efficiency.

Critical Pre-Installation and Safety Protocols

Before the first batch of ice is made, several non-negotiable steps must be followed to ensure safety and machine integrity. Upon delivery, the unit must remain upright for 24 hours before being plugged in. This allows the compressor oil, which may have shifted during transit, to settle back into the compressor. Failing to do this can cause severe compressor damage, a common point of failure emphasized by HVAC technicians on forums. Furthermore, the ice maker must be connected to a potable drinking water supply with a specific pressure range of 14.5-58 psi. Water pressure outside this range requires a changeover valve to prevent mechanical issues and ensure consistent ice production.

Safety is paramount. The included three-prong plug must be connected to a properly grounded outlet. Using an extension cord is strongly discouraged as it can lead to voltage drop, overheating, and a serious fire hazard—a risk frequently cited by electrical safety authorities. The unit must also be kept away from flammable materials and heat sources like stoves or direct sunlight, which can force the compressor to overwork and reduce its lifespan.

Optimizing Installation for Peak Performance

Proper physical installation is just as critical as electrical and water hookups. The manufacturer specifies leaving at least 5.9 inches (15 cm) of clearance on all four sides of the machine. This ventilation space is essential for heat dissipation from the condenser coils. Restricted airflow is a leading cause of inefficiency and premature system failure in commercial refrigeration equipment. The unit’s overall dimensions of 26.4” W x 23.2” D x 61.4” H make it a substantial piece of equipment, so planning for this footprint and the necessary clearance is a key step in kitchen design.

Equally important is the drainage system. Since ice in the storage bin will naturally melt, a gravity-fed drain pipe must be connected before operation. The drain outlet must be positioned lower than the ice maker’s outlet to ensure proper flow. Neglecting this will result in water accumulating inside the unit, leading to potential overflow, ice clumping, and sanitation issues. For operations considering high-volume ice production, exploring a model like the high-capacity commercial stainless steel ice maker can provide greater storage and output to meet demanding needs.

Operational Longevity and Best Practices

To maximize the return on your investment, adhering to ongoing best practices is crucial. Use only clean, potable water in the unit. Introducing other liquids or water with high mineral content can damage the evaporator plate, clog water lines, and produce poor-quality ice. Regular cleaning and descaling, as per the manufacturer’s instructions, are essential to prevent scale buildup, which insulates the evaporator and drastically reduces efficiency—a common maintenance topic in restaurant management subreddits.

Understand that the surrounding ambient temperature directly influences ice production cycles. In hotter environments, the compressor works harder and ice-making cycles may take longer. This is a normal function of refrigeration physics. The machine is designed for indoor use; outdoor installation exposes it to uncontrolled elements, leading to erratic performance and accelerated wear. For businesses with evolving needs, the scalable solution of a commercial stainless steel ice maker offers the durability and output required for growth.

Conclusion: A Strategic Investment for Your Business

Selecting and installing a commercial ice maker is a significant decision that impacts daily operations. This heavy-duty model, with its durable stainless steel build and efficient R290 refrigerant system, is engineered for the rigors of food service. However, its technical potential is only unlocked through meticulous attention to the installation and safety guidelines. From the mandatory 24-hour settling period and precise water pressure requirements to ensuring adequate ventilation and proper drainage, each step is foundational to reliable performance.

Ignoring these protocols can lead to reduced efficiency, higher energy costs, frequent breakdowns, and even safety hazards. By treating the ice maker as a core piece of kitchen infrastructure—requiring proper site preparation, professional-grade connections, and routine maintenance—you safeguard your investment. This ensures a consistent, high-volume supply of ice, which is the lifeblood of beverage service, food presentation, and customer satisfaction in the hospitality industry. Ultimately, the right stainless steel commercial ice maker, correctly installed and maintained, transitions from a mere appliance to a dependable partner in your business’s success, supporting seamless service during your busiest hours.

This guide really clarifies the key specs and safety steps for setting up a heavy-duty commercial ice maker.

\}}

This guide really clarifies the key specs and safety steps for setting up a heavy-duty commercial ice maker.

\}}

This guide really clarifies the key specs and safety steps for setting up a heavy-duty commercial ice maker.

\}}

Great guide on heavy-duty commercial ice makers—really helpful for understanding the key specs and safety steps before setting one up.

\}}