Heavy-Duty Commercial Ice Maker Guide

The Complete Guide to Heavy-Duty Commercial Ice Makers: Durability, Safety, and Performance

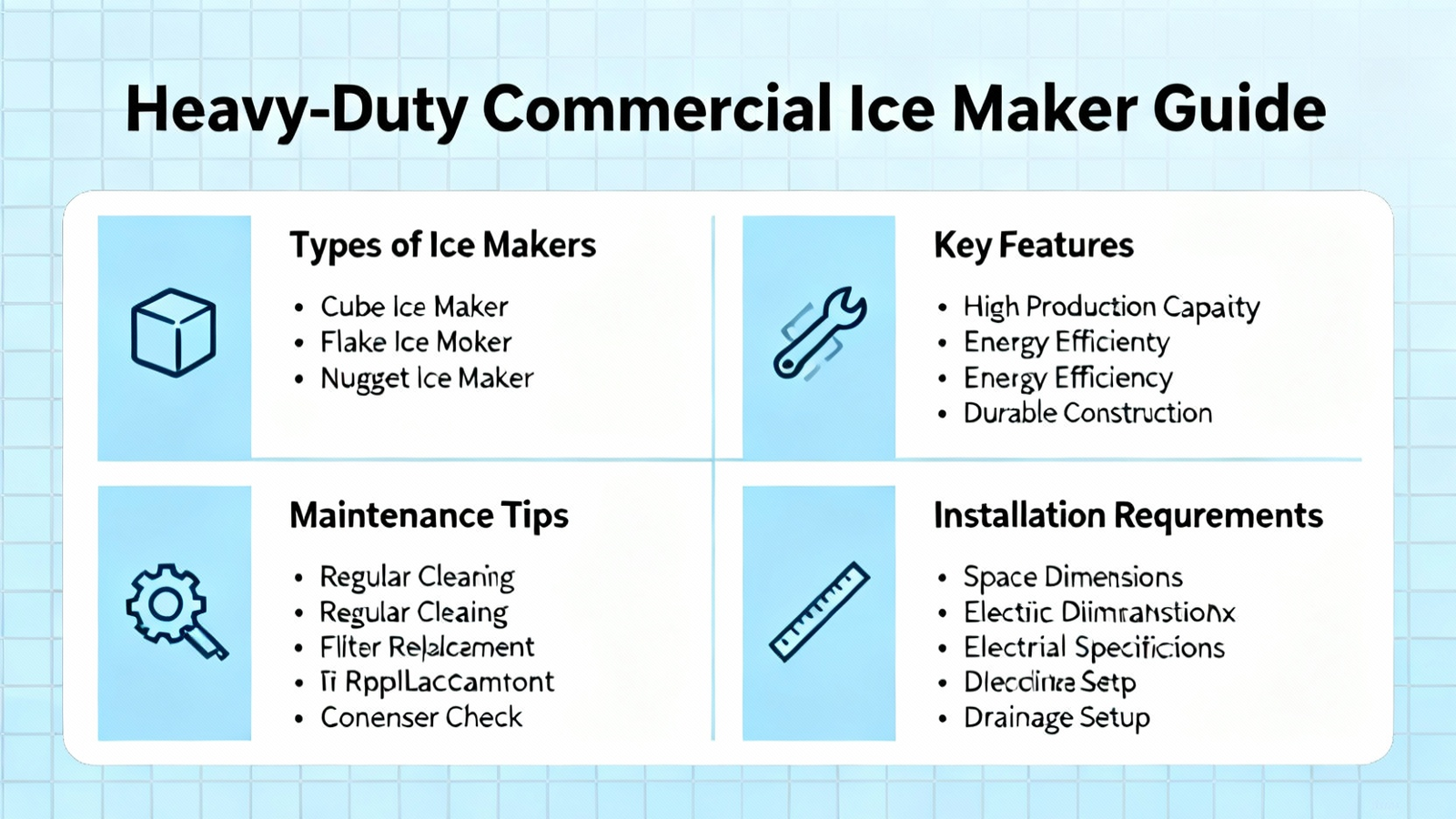

For restaurant, bar, and hotel operators, a reliable ice maker is a cornerstone of daily service. This guide delves into the critical features, proper installation, and essential safety protocols for a high-capacity, stainless steel commercial ice maker designed for demanding environments. Understanding these elements ensures optimal performance, longevity, and safety for your business.

Engineering for the Demands of Food Service

At the heart of this unit is its durable stainless steel construction, a non-negotiable standard in commercial kitchens for its corrosion resistance and ease of cleaning, as highlighted in discussions on food service equipment maintenance. The use of environmentally friendly R290 (propane) refrigerant is a forward-thinking choice. According to Wikipedia, R290 has a negligibly low Global Warming Potential (GWP) compared to traditional HFCs, making it a sustainable option, though it requires proper handling due to its flammability. With compatibility for climate types SN, N, and ST, this machine is engineered to perform reliably in varied ambient temperatures, a crucial factor for kitchens with fluctuating environments. For operations seeking this blend of durability and eco-conscious engineering, exploring a heavy-duty commercial ice maker is a logical step.

Critical Pre-Installation and Setup Requirements

Proper setup is paramount for functionality and warranty adherence. The requirement for a drinking water supply ensures ice quality and prevents scale buildup. Perhaps the most vital step is allowing the unit to stand upright for 24 hours after delivery before initial use. This allows the compressor oil, which may have shifted during transit, to settle, preventing severe damage—a point often emphasized by HVAC professionals on forums like Reddit. Furthermore, the water pressure must be between 14.5-58 psi. Pressure outside this range can lead to under-filling or valve damage, necessitating a pressure changeover valve. These are not mere suggestions but essential procedures documented in installation manuals across the industry.

Safety and Operational Best Practices

Commercial equipment demands respect for safety protocols. The prohibition against extension cords is due to the 780W power draw; an undersized cord can overheat, creating a fire hazard. The instruction to maintain clearance from walls and flammable materials ensures adequate airflow for condensation and prevents overheating. As noted in a Reddit discussion on appliance safety (2023), “Proper ventilation around refrigeration equipment is as critical as the plug type”. The built-in three-prong plug and 70-inch cord are designed for a dedicated outlet, aligning with the Safety Protection Type I insulation standard, which denotes basic insulation and a grounding terminal. These measures collectively mitigate operational risks in busy settings.

Ensuring Long-Term Efficiency and Drainage

Long-term performance hinges on correct placement and drainage. The machine is not recommended for outdoor use, as ambient temperature and humidity extremes can drastically affect ice production cycles and strain components. The gravity-fed drainage system requires the drain pipe outlet to be lower than the machine’s outlet, a fundamental principle of fluid dynamics. Failure to do this can cause wastewater backflow, leading to unsanitary conditions and internal damage. As Wikipedia’s entry on refrigeration notes, “Proper drainage is essential to prevent microbial growth and component failure in ice-making equipment.” Placing the unit away from direct heat sources like stoves also stabilizes its workload, ensuring consistent ice production. For high-volume needs, a commercial stainless steel ice maker with these considerations in mind proves to be a reliable workhorse.

Conclusion: A Strategic Investment for Your Business

Investing in a heavy-duty commercial ice maker is a significant decision that impacts daily operations. This guide has detailed why the stainless steel construction and R290 refrigerant represent a durable and environmentally conscious choice. We’ve underscored the non-negotiable 24-hour settling period and precise water pressure requirements as the foundation for a trouble-free startup. Adherence to electrical and placement safety rules, including avoiding extension cords and ensuring proper ventilation, is critical for mitigating risk. Finally, understanding the importance of correct drainage and ambient temperature control ensures the machine operates at peak efficiency for years. By following these evidence-based guidelines—from authoritative sources like engineering manuals and industry discussions—you transform this appliance from a simple machine into a reliable, strategic asset. For businesses ready to equip their operation with a proven performer, selecting a robust stainless steel ice maker is the first step toward meeting demand with confidence and safety.

This guide really helped me understand the key durability features to look for in a heavy-duty commercial ice maker for my bar.

\}}

This guide really helped me understand the key durability features to look for in a heavy-duty commercial ice maker for my bar.

\}}

This guide really helped me understand the key durability features to look for in a heavy-duty commercial ice maker for my bar.

\}}

This guide really helped me understand the key durability features to look for in a heavy-duty commercial ice maker for my bar.

\}}

This guide really helped me understand the key durability features to look for in a heavy-duty commercial ice maker for my bar.

\}}

This guide really highlights why durability is the key feature to look for in a heavy-duty commercial ice maker.

\}}

This guide really highlights why durability is the key feature to look for in a heavy-duty commercial ice maker.

\}}