Commercial Stainless Steel Ice Maker Guide for Businesses

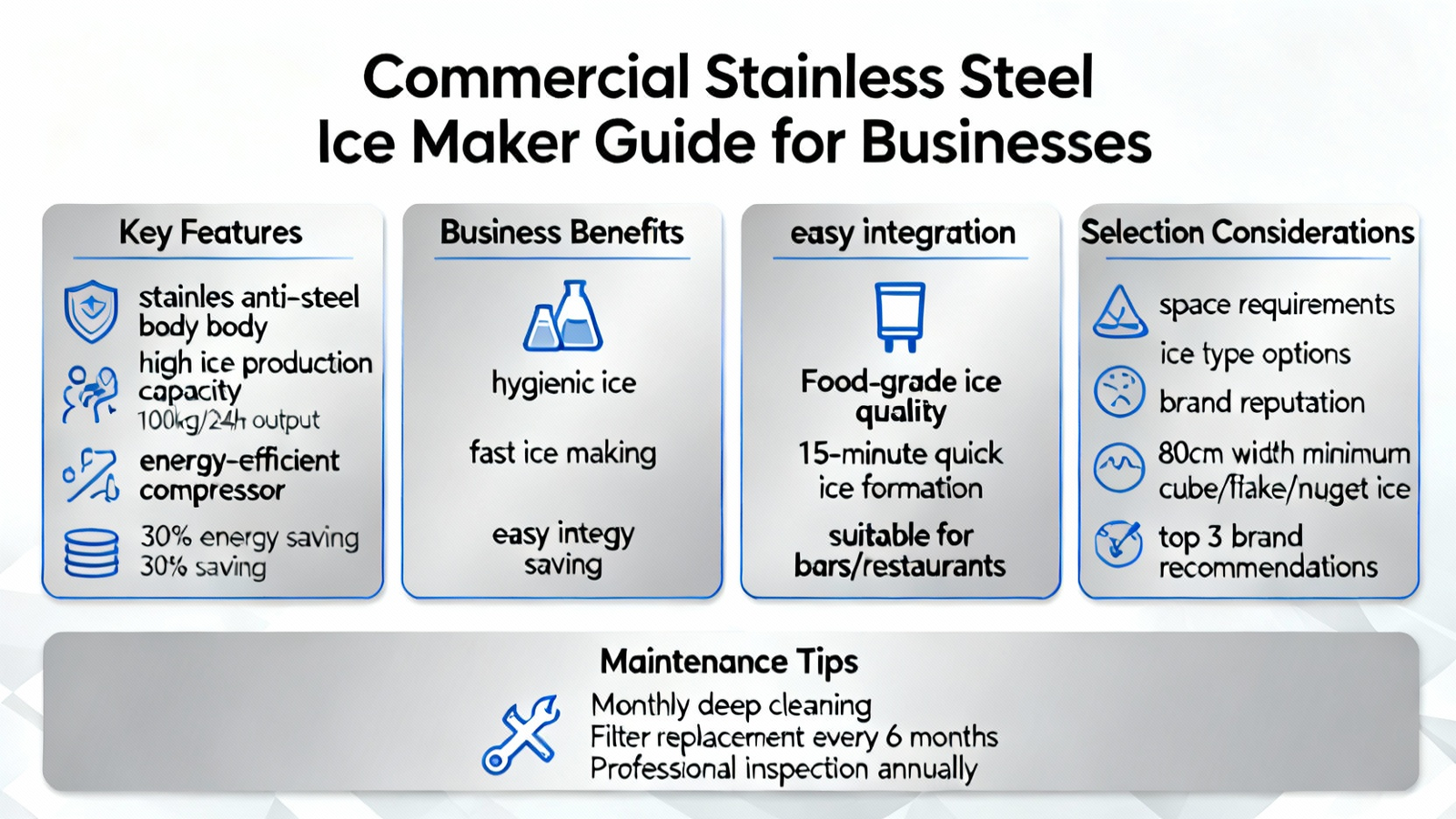

For restaurants, bars, and hotels, a reliable ice maker is a cornerstone of daily operations. This guide delves into the critical specifications, installation requirements, and safety protocols for a heavy-duty commercial ice maker built with durable stainless steel. Understanding these details is key to ensuring optimal performance, longevity, and safety in your foodservice business.

Engineering for Commercial Endurance

This unit is engineered for the harsh demands of a commercial kitchen. Its durable stainless steel construction is not just for aesthetics; it resists corrosion, withstands frequent cleaning with harsh chemicals, and maintains hygiene—a critical factor in foodservice. The use of environmentally friendly R290 (propane) refrigerant is a significant modern upgrade. According to Wikipedia, R290 has a “negligible ozone depletion potential and very low global warming potential” compared to traditional hydrofluorocarbons (HFCs), aligning with newer environmental standards. With compatibility for climate types SN, N, and ST, it is designed for reliable performance in varied environmental conditions common across the United States.

Critical Installation & Setup Protocols

Proper installation is non-negotiable for performance and warranty. The unit requires a drinking water supply with precise pressure (14.5-58 psi) to function correctly. A dedicated drain line, installed lower than the machine’s outlet, is mandatory for wastewater removal via gravity. Perhaps the most crucial step is allowing the unit to settle upright for 24 hours after delivery before initial use. This allows internal compressor oil to settle, preventing damage. As noted in a Reddit discussion on appliance setup, a user emphasized, “Always let it stand… moving it can cause oil to flood the lines,” highlighting a widely endorsed practice. Adequate clearance (at least 5.9 inches on all sides) ensures proper airflow and heat dissipation.

Operational Safety & Best Practices

Safety in a busy commercial setting is paramount. The ice maker’s electrical design includes a three-prong plug for proper grounding, and using an extension cord is strongly discouraged due to overheating and fire risk. The unit must be kept away from flammable materials and heat sources like stoves. It is designed for indoor use only; outdoor operation exposes it to elements and temperature extremes it is not rated for. Furthermore, only potable water should be used. Introducing other liquids can damage the system and create unsafe ice. These guidelines align with general commercial equipment safety principles often reiterated by professionals in forums like r/KitchenConfidential, where proper equipment maintenance is a frequent topic.

Maximizing Performance and Longevity

To ensure the machine meets its capacity potential, operators must account for ambient conditions, as environmental temperature directly influences ice production time. Placing it away from direct sunlight and other heat sources stabilizes its internal temperature. Regular maintenance, implied by the need for clean water and a proper drain, is essential. For businesses seeking a model that embodies these features, exploring a unit like the 23.23 in. 750 lbs./24h Capacity Commercial Stainless Steel Ice Maker provides a benchmark. Consistent care, as with any major commercial stainless steel ice maker, directly translates to consistent ice supply and reduced long-term operating costs.

Conclusion

Investing in a heavy-duty commercial ice maker is a significant decision that impacts daily operations. This analysis underscores that beyond the robust stainless steel construction and efficient R290 refrigerant system, the true value and reliability of the unit are unlocked through meticulous adherence to installation and safety protocols. From ensuring proper water pressure and drainage to allowing critical settling time and providing adequate ventilation, each step is foundational. The operational guidelines—prohibiting outdoor use, extension cords, and non-water inputs—are not mere suggestions but essential practices to mitigate risk and ensure food safety. As evidenced by discussions within professional communities like Reddit’s appliance and kitchen forums, these principles are widely recognized as standard for protecting such a capital investment. Ultimately, a commercial ice maker of this caliber, when installed and operated correctly, becomes a dependable workhorse. It delivers the essential volume of ice required by high-demand establishments while offering durability and efficiency that, with proper care, will support business needs for years to come.

This guide really highlights why a durable stainless steel ice maker is such a crucial investment for any busy food service operation.

\}}

This guide really highlights why a durable stainless steel ice maker is such a crucial investment for any busy food service operation.

\}}

This guide really highlights why a durable stainless steel ice maker is such a crucial investment for any busy food service operation.

\}}

This guide really highlights why a durable stainless steel ice maker is such a crucial investment for any busy food service operation.

\}}

This guide really highlights why a durable stainless steel ice maker is such a crucial investment for any busy food service operation.

\}}

This guide really highlights why a durable stainless steel ice maker is such a crucial investment for any busy food service operation.

\}}

This guide really highlights why a durable stainless steel ice maker is such a crucial investment for any busy food service operation.

\}}