Commercial Stainless Steel Ice Maker Guide for Businesses

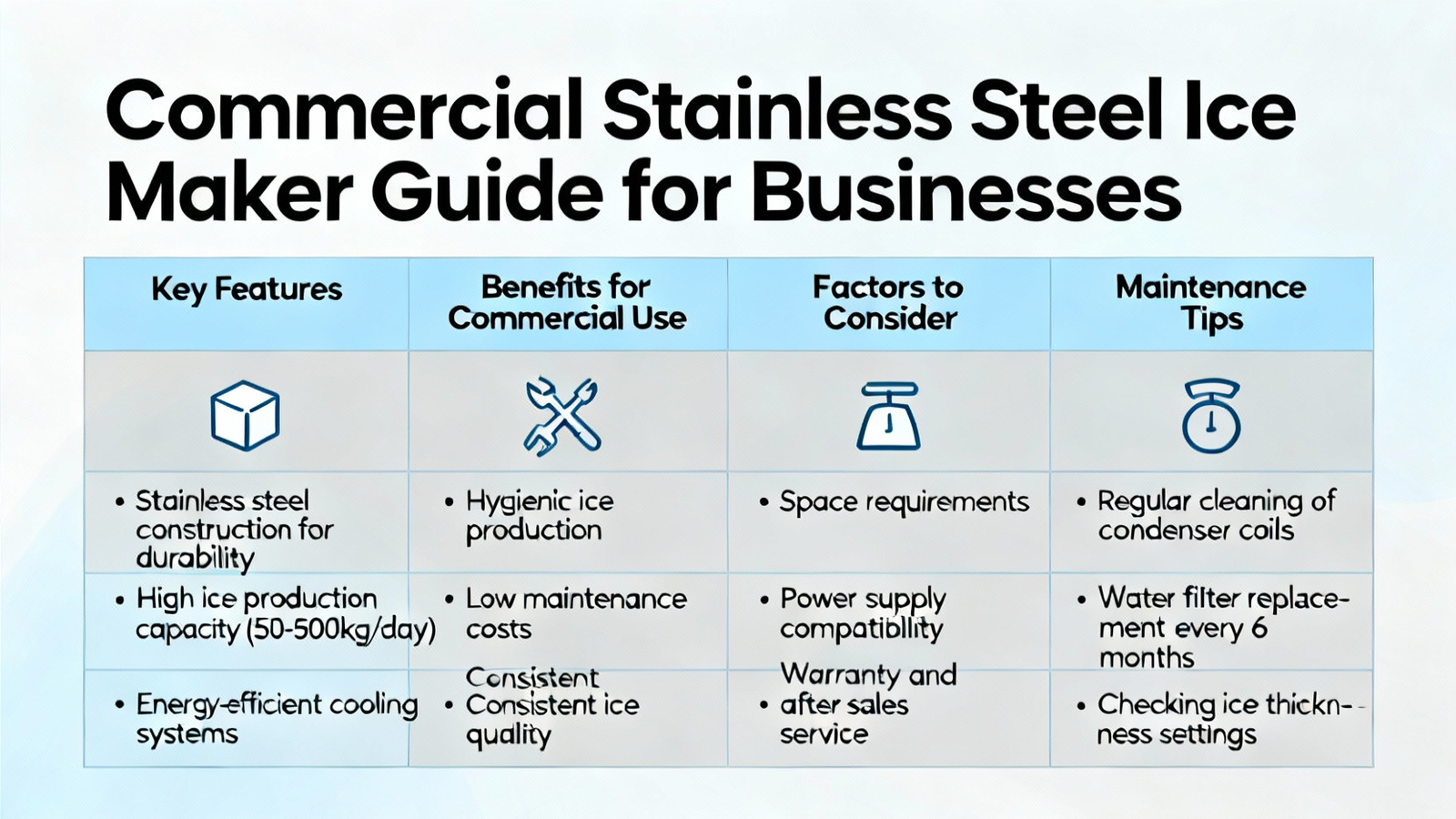

For restaurants, bars, and hotels, a reliable ice maker is a cornerstone of daily operations. This guide delves into the critical features, installation requirements, and safety protocols for a heavy-duty commercial ice maker built with durable stainless steel. Understanding these details ensures optimal performance, longevity, and safety for your business, safeguarding your investment and supporting seamless service.

Engineering for Endurance and Efficiency

At the core of this unit is its durable stainless steel construction, a material chosen for its corrosion resistance, ease of cleaning, and ability to withstand the high-demand environments of commercial kitchens. The use of environmentally friendly R290 (propane) refrigerant is a significant modern advancement. According to Wikipedia, R290 has a “negligible ozone depletion potential and very low global warming potential” compared to traditional hydrofluorocarbons (HFCs), making it a more sustainable choice. This, combined with its compatibility with climate types SN, N, and ST, means the machine is engineered for reliable performance in varied environments, from consistently cool to seasonally tropical settings.

Critical Installation and Setup Protocols

Proper installation is non-negotiable for functionality and safety. The unit requires a drinking water supply with precise pressure between 14.5-58 psi; outside this range, a pressure changeover valve is mandatory to prevent damage. A gravity-fed drainage pipe, with its outlet lower than the machine’s, must be connected to handle meltwater. Perhaps the most crucial step is allowing the unit to settle upright for 24 hours after delivery before initial use. This allows the refrigerant and oils to stabilize, a point often emphasized by industry professionals on forums like Reddit. A user in a 2023 discussion on r/KitchenConfidential advised, “Always let your commercial refrigeration units rest after transport. You’ll save yourself a costly compressor repair.”

Operational Safety and Best Practices

Adhering to operational guidelines ensures safety and maximizes the lifespan of your commercial stainless steel ice maker. Key mandates include:

- Providing at least 5.9 inches of clearance on all sides for proper airflow and heat dissipation.

- Never using an extension cord, as the 780W draw requires a direct connection to a 110V/60Hz outlet to prevent overheating and fire risk.

- Keeping the unit away from flammable materials, direct sunlight, and heat sources like stoves.

- Using only water to make ice, as other liquids can damage the system and create contamination hazards.

These practices are aligned with general commercial equipment safety standards, which stress proper ventilation and dedicated power circuits.

Maximizing Performance and Longevity

To ensure your ice maker delivers its full 750 lbs./24h capacity, ongoing care is essential. Recognize that surrounding environmental temperature will influence ice-making time; production is faster in cooler conditions. Regular cleaning and descaling, as per the manufacturer’s instructions, prevent mineral buildup that can impair efficiency. Furthermore, the unit’s Safety Protection Type I designation indicates it is designed for use in environments where protection against electric shock is provided by basic insulation and no reliance on a conductive earth ground, underscoring the importance of professional installation in a compliant electrical system.

In summary, a commercial ice maker like this stainless steel model is a significant investment that demands informed handling. Its durable construction and eco-friendly R290 refrigerant offer modern efficiency, but this is fully realized only through meticulous installation—including proper water pressure, mandatory drainage, and the critical 24-hour settling period. Strict adherence to safety protocols, such as avoiding extension cords and ensuring ample clearance, protects both your staff and your asset. Finally, understanding that factors like ambient temperature affect performance allows for better operational planning. By integrating these technical specifications, safety mandates, and performance insights, you secure a reliable ice supply that meets the relentless demands of your hospitality business, ensuring this essential equipment operates effectively for years to come.

This guide really highlights why a durable stainless steel ice maker is such a smart investment for busy operations.

\}}

This guide really highlights why a durable stainless steel ice maker is such a smart investment for busy operations.

\}}

This guide really highlights why a durable stainless steel ice maker is such a smart investment for busy operations.

\}}

This guide really highlights why a durable stainless steel ice maker is such a smart investment for busy operations.

\}}

This guide really highlights why a durable stainless steel ice maker is such a smart investment for busy operations.

\}}

This guide really highlights why a durable stainless steel ice maker is such a smart investment for busy operations.

\}}