Commercial Ice Makers: Efficiency, Filtration & Durability

In the demanding world of commercial food service and hospitality, a reliable ice maker is not a luxury—it’s a necessity. This article explores the advanced engineering and user-centric design of modern, high-capacity ice makers, focusing on how features like integrated water filtration, efficient cooling systems, and robust construction converge to meet rigorous commercial standards while promoting sustainability and operational ease.

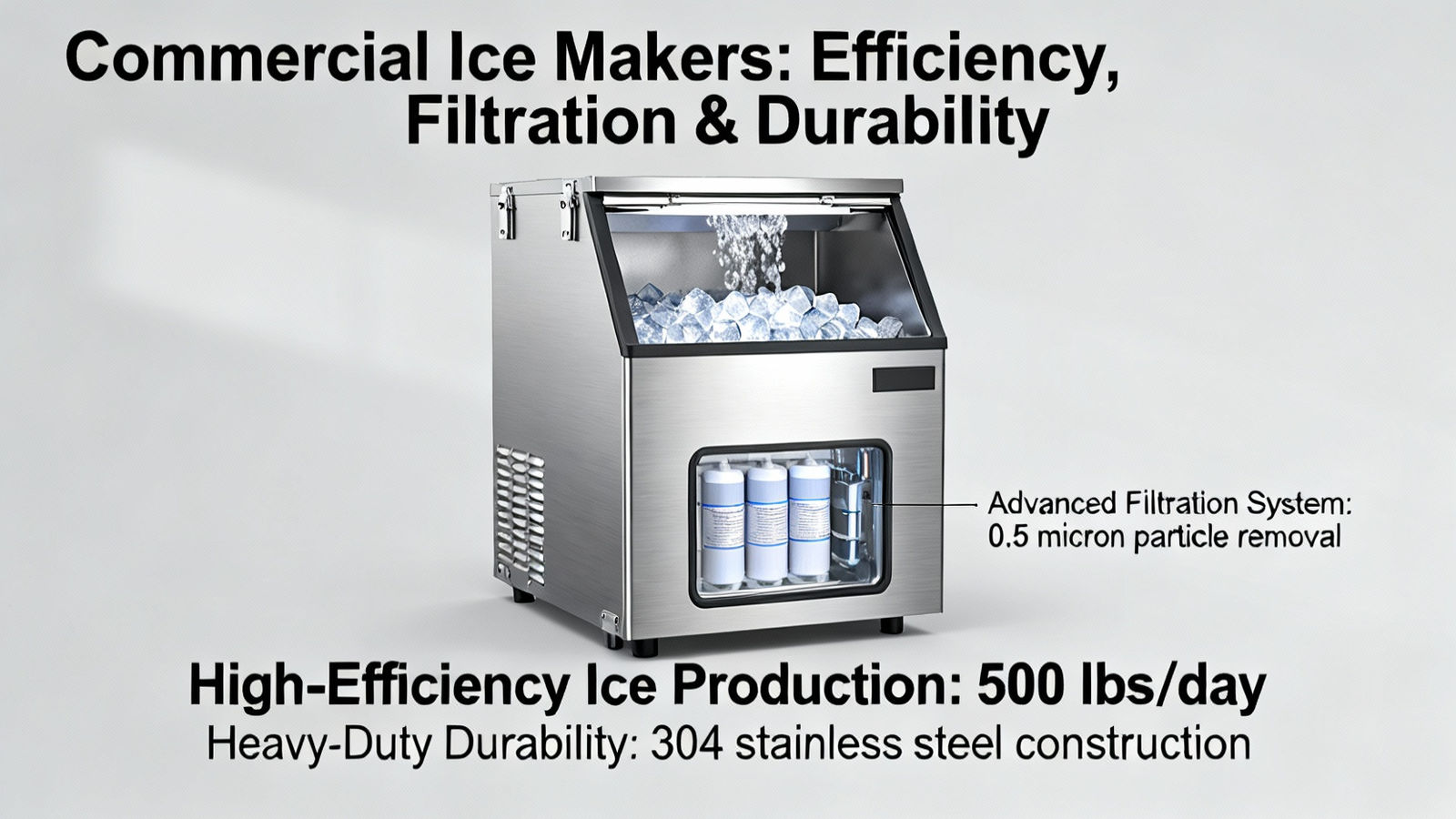

Purity at the Source: The Critical Role of Integrated Filtration

The quality of ice is directly tied to the quality of the water used to make it. Impurities in water lines, such as minerals, chlorine, or sediment, can affect ice clarity, taste, and even the machine’s internal components. An integrated drinking water filter is essential for ensuring crystal-clear ice and pure-tasting beverages. This is supported by discussions in communities like r/KitchenConfidential, where industry professionals frequently emphasize the importance of clean water lines and filtration to prevent scale buildup and maintain ice quality. A built-in filter addresses this proactively, serving as a first line of defense for both the machine’s longevity and the end product.

Engineering for Efficiency and Endurance

Commercial ice makers must perform reliably under constant strain. Key to this is a low-noise compressor and an advanced cooling system. The use of environmentally friendly refrigerants like R290 (propane), noted for its low global warming potential as per Wikipedia’s entry on R-290, represents a shift toward sustainable commercial appliances. Coupled with multiple fans and stainless steel hot air outlets, these systems enable rapid heat dissipation for faster ice cycles. This engineering focus on thermal management, crucial for 24/7 operation, is what allows a unit like the 24.3 in. 200 lbs./24h Stainless Steel Built-In Filter Commercial Ice Maker to achieve a production capacity exceeding 7,500 cubes per day while ensuring component durability.

Intelligent Design for Simplified Operation

Beyond raw power, intelligent features that reduce labor and maintenance are paramount. An automatic self-cleaning function helps prevent biofilm and scale accumulation, a common point of failure highlighted in equipment maintenance threads. Adjustable ice thickness provides versatility, allowing the same machine to serve different purposes, from chilling delicate salads to standing up slowly in a cocktail. User-centric additions like a flip-up door for easy access, a included ice scooper, and stable adjustable feet streamline daily interaction. These design choices reflect a deep understanding of the fast-paced commercial environment, where time saved on maintenance directly impacts operational efficiency.

Built for the Long Haul: Commercial Durability

The final differentiator for any commercial appliance is its construction. In a high-moisture, high-use setting, materials matter. A stainless steel exterior and interior components resist corrosion and are easier to sanitize, aligning with health code requirements. The substantial 55 lb. storage bin capacity ensures a ready supply during peak hours. This build quality is an investment, designed to withstand the test of time and volume, preventing costly downtime and replacements. As noted in industry reviews and discussions, the robustness of the chassis and internal parts is often the deciding factor for buyers comparing commercial-grade versus residential-grade equipment.

Choosing a commercial ice maker is a significant decision that impacts daily operations, customer satisfaction, and long-term overhead. As we have explored, the ideal machine synthesizes several critical elements: it must guarantee purity through integrated filtration, harness efficient and sustainable cooling technology, simplify operation with automated features, and be constructed from durable, commercial-grade materials. Units that embody these principles, such as the 24.3 in. 200 lbs./24h Stainless Steel Built-In Filter Commercial Ice Maker, offer more than just ice—they provide reliability. They address the real-world concerns of maintenance staff and business owners, from the importance of clean water lines discussed by professionals online to the sustainable advantages of modern refrigerants. In conclusion, compromising on any of these facets can lead to increased maintenance costs, inconsistent product quality, and operational disruptions. Investing in a comprehensively engineered solution ensures that this vital piece of equipment becomes a dependable asset, supporting seamless service and contributing to a professional establishment’s reputation for quality, one perfectly clear cube at a time.