Commercial Ice Maker Guide: Specs, Setup, Safety Tips

Mastering Your Heavy-Duty Commercial Ice Maker: A Complete Guide

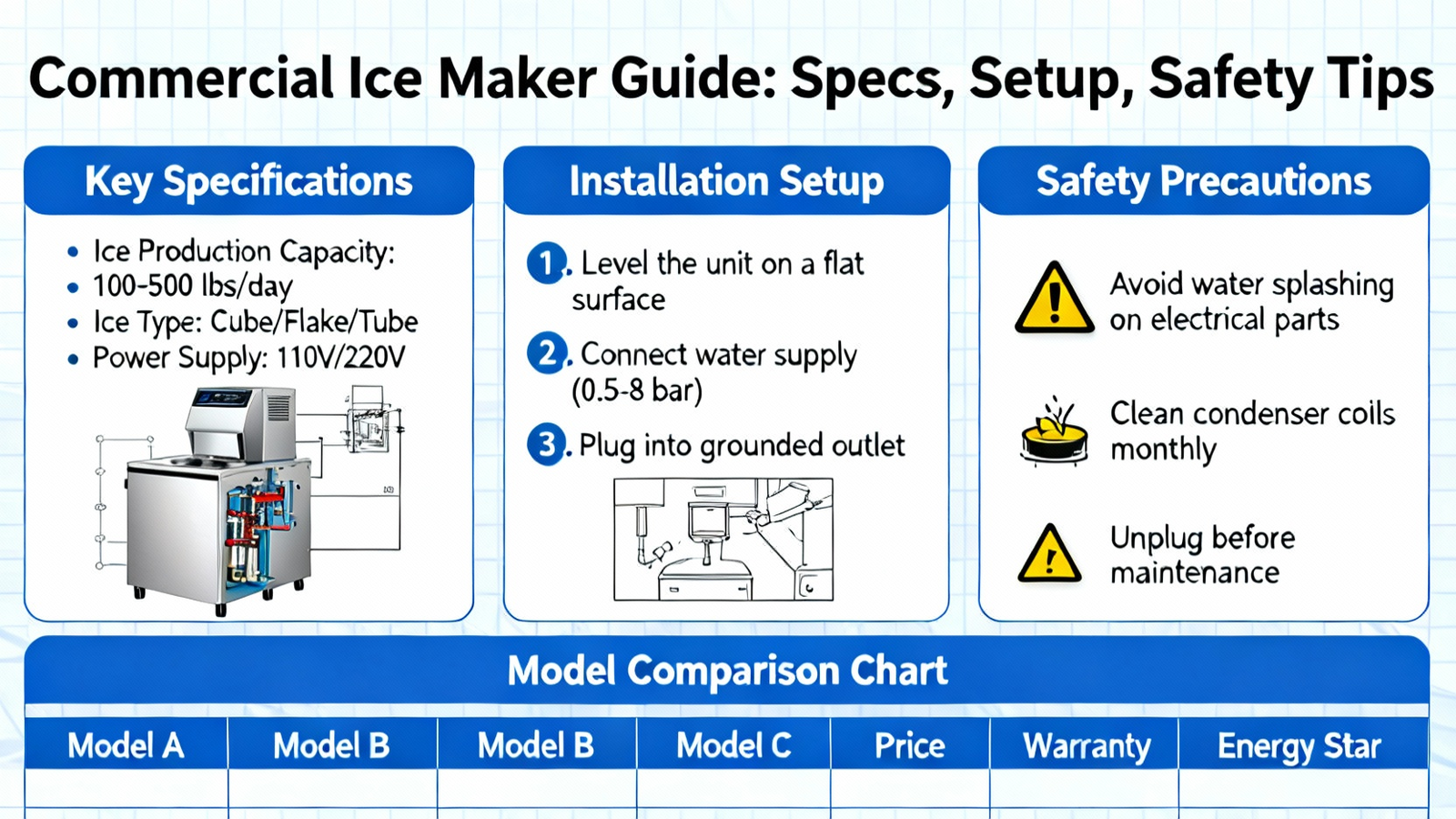

For restaurants, bars, and hotels, a reliable ice maker is the backbone of service. This guide delves into the specifics of a durable, stainless steel commercial unit, covering its robust specifications, critical installation requirements, and essential safety protocols to ensure longevity and peak performance in your business.

Engineered for Demanding Environments

This commercial ice maker is built with a focus on durability and operational efficiency. Its stainless steel construction is industry-standard for food service equipment, offering superior corrosion resistance and ease of cleaning, as noted in discussions on equipment longevity in the r/KitchenConfidential community. Designed for 110V 60Hz operation, it integrates seamlessly into standard US commercial kitchens without requiring special electrical upgrades. The use of R290 (propane) refrigerant is a forward-thinking choice; this natural refrigerant has a very low Global Warming Potential (GWP) compared to traditional HFCs, aligning with growing environmental regulations as detailed on Wikipedia’s R-290 page. Its compatibility with multiple climate types (SN, N, ST) ensures reliable ice production from cooler subtropical to temperate environments.

Critical Pre-Installation and Safety Protocols

Before powering on your new commercial ice maker, adherence to safety and setup guidelines is non-negotiable. The unit’s Safety Protection Type I designation indicates it is grounded for electrical safety. Key warnings from the manual are not mere suggestions:

- Ventilation & Placement: Maintaining at least 5.9 inches of clearance on all sides is crucial for airflow and heat dissipation, preventing compressor failure.

- Power & Fire Safety: The prohibition against extension cords and keeping the unit away from flammables addresses a real hazard; the 780W power draw requires a dedicated outlet to prevent overheating.

- Initial Setup: The 24-hour settling period after delivery is vital. As explained by technicians on forums like r/refrigeration, this allows oil in the compressor to settle, preventing damage upon startup.

Optimizing Water Supply and Drainage

Proper water and waste management are the most common points of failure in ice maker installation. The unit requires a potable water line with a pressure between 14.5 and 58 PSI. Pressure outside this range can lead to slow ice production or valve damage, necessitating a pressure regulator. Equally important is the gravity-fed drainage system. The drain outlet must be lower than the ice maker’s outlet to prevent wastewater backflow, which can cause microbial growth and machine malfunction. This aligns with standard plumbing codes for commercial appliances to ensure sanitary operation.

Ensuring Long-Term Performance and Output

To guarantee your stainless steel ice maker meets your business’s daily ice needs, understand the factors affecting production. Ambient temperature directly influences cycle times; a kitchen consistently above 90°F will see reduced output. Placing the unit away from heat sources like ovens and direct sunlight is critical. Furthermore, using only clean, filtered water prevents scale buildup, a primary cause of maintenance calls. Regular cleaning, as per the manufacturer’s schedule, is essential. As emphasized in food safety guidelines, proper maintenance prevents contamination and ensures the ice is safe for customer consumption, protecting both your patrons and your reputation.

Conclusion: A Strategic Investment for Your Business

Integrating this heavy-duty commercial ice maker into your operation is more than just plugging in an appliance; it’s a strategic investment in your service infrastructure. Its durable stainless steel build and environmentally conscious R290 refrigerant system offer a reliable and modern solution. Success hinges on meticulous attention to the outlined protocols: ensuring proper electrical and water connections, allowing for critical settling time, maintaining clearances for ventilation, and establishing a correct drainage path. By following these guidelines—rooted in manufacturer specs, technician advice from communities like r/refrigeration, and standard food service practices—you secure consistent ice production. This reliability supports seamless daily operations, enhances customer satisfaction, and provides a return on investment through years of dependable performance in your restaurant, bar, hotel, or catering business. Proper setup and care transform this piece of equipment from a simple machine into a cornerstone of your operational efficiency.