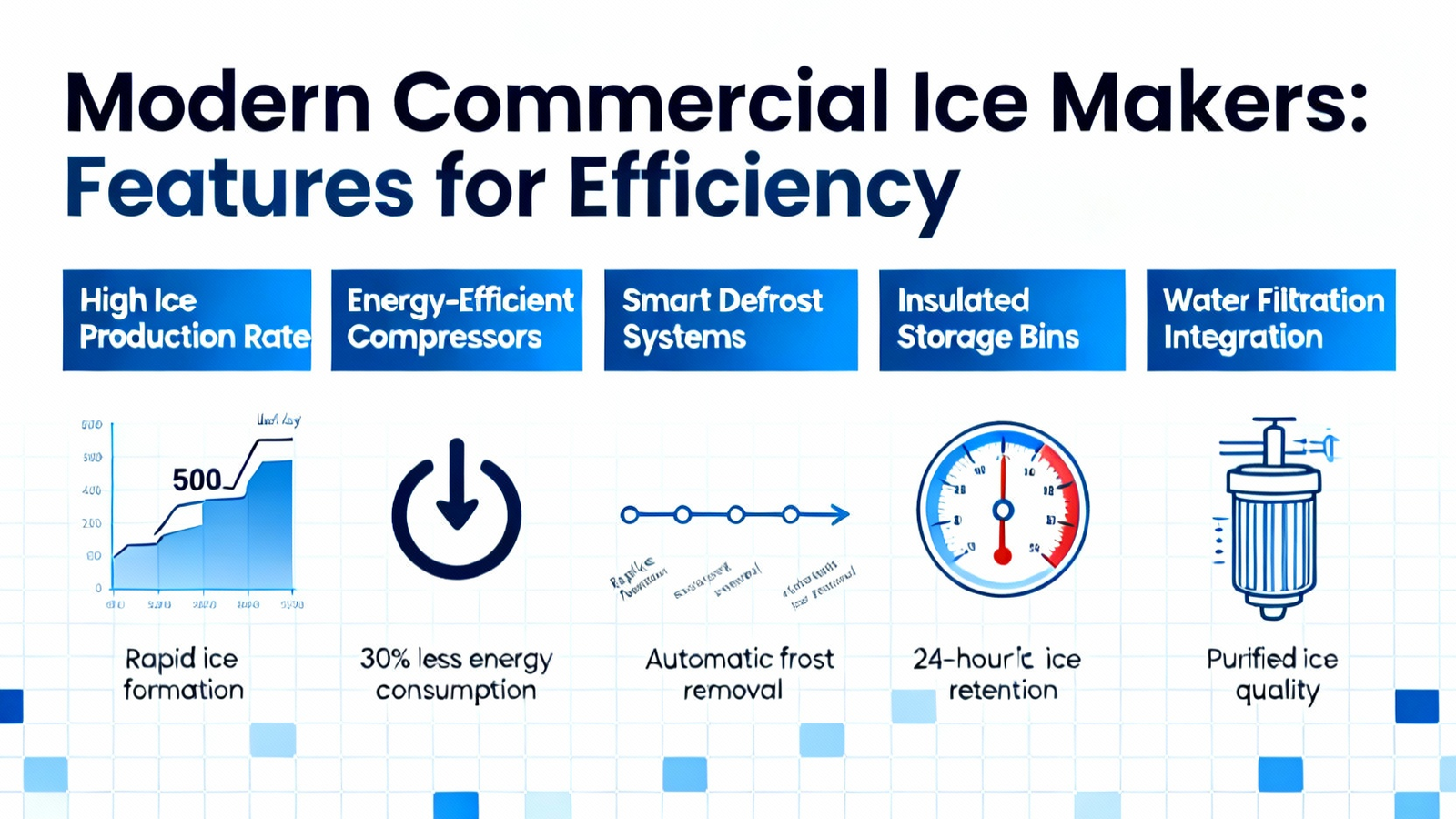

Modern Commercial Ice Makers: Features for Efficiency

For any business that relies on a steady supply of ice, from bustling restaurants to high-traffic hotels, a commercial ice maker is a critical asset. This article explores the advanced features of modern commercial ice makers, focusing on how innovations like fault alerts, auto-defrost, and large-capacity production ensure operational efficiency, hygiene, and uninterrupted service for demanding environments.

Intelligent Operation for Uninterrupted Production

Modern commercial ice makers are engineered for autonomy and reliability. Key to this is the integrated fault alert system, which monitors machine functions and notifies staff of issues before they halt production. This is complemented by a water shortage alert, preventing damage to the compressor—a common point of failure. As noted in a discussion on r/refrigeration (2023), proactive alerts are crucial for avoiding costly downtime. These features, combined with an intuitive touch control panel, shift the role of staff from constant monitoring to simple oversight.

Hygiene, Maintenance, and Installation Ease

Maintaining ice quality and machine longevity is simplified through automated features. The auto-defrost function eliminates the labor-intensive and often-neglected task of manual defrosting, which according to Wikipedia helps maintain consistent ice production and energy efficiency. A built-in water filter is essential for producing clean, clear ice and protecting internal components from scale buildup. Furthermore, practical design elements like 4-adjustable feet ensure a level installation, which is vital for proper water distribution and preventing uneven ice production, a point often emphasized by installers in online forums.

High-Capacity Design for Demanding Environments

The core purpose of a commercial unit is to meet high-volume demand. A machine like the 22.24 in. 420 lbs/24h Commercial Split Ice Maker addresses this by producing over 14,900 cubes daily, stored in a large 300 lb. capacity bin. This split design, where the ice maker and storage bin are separate, allows for flexible installation and greater storage. The blue lighted storage bin is not just aesthetic; it serves as a functional visual indicator of ice levels in low-light bar or kitchen areas, enhancing both practicality and ambiance.

User-Centric Accessibility and Drainage

The final considerations for a commercial ice maker focus on daily user interaction and maintenance. Features like a flip-up ice bin door and included ice scoop promote quick, hygienic access without contaminating the ice supply. Effective drainage is also critical for sanitation and operation. The best units offer flexibility, providing both water pump drainage and gravity drainage options for the storage bin to accommodate different installation layouts, ensuring proper water management as highlighted in technical guides for foodservice equipment.

In summary, today’s commercial ice makers, such as the high-performance split ice maker model, represent a significant leap from basic ice production. They are intelligent systems designed to ensure operational resilience through proactive fault and water alerts, reduce labor through auto-defrost, and guarantee ice quality with integrated filtration. Their high-capacity design, capable of producing hundreds of pounds of ice daily, meets the needs of the busiest establishments. When paired with user-friendly features like adjustable leveling feet, intuitive controls, lighted bins, and flexible drainage, these machines offer a comprehensive solution. Investing in a unit with these advanced features is an investment in consistency, sanitation, and ultimately, customer satisfaction, ensuring that your business never runs out of this essential commodity. For establishments seeking a reliable powerhouse, a modern commercial ice maker is indispensable.