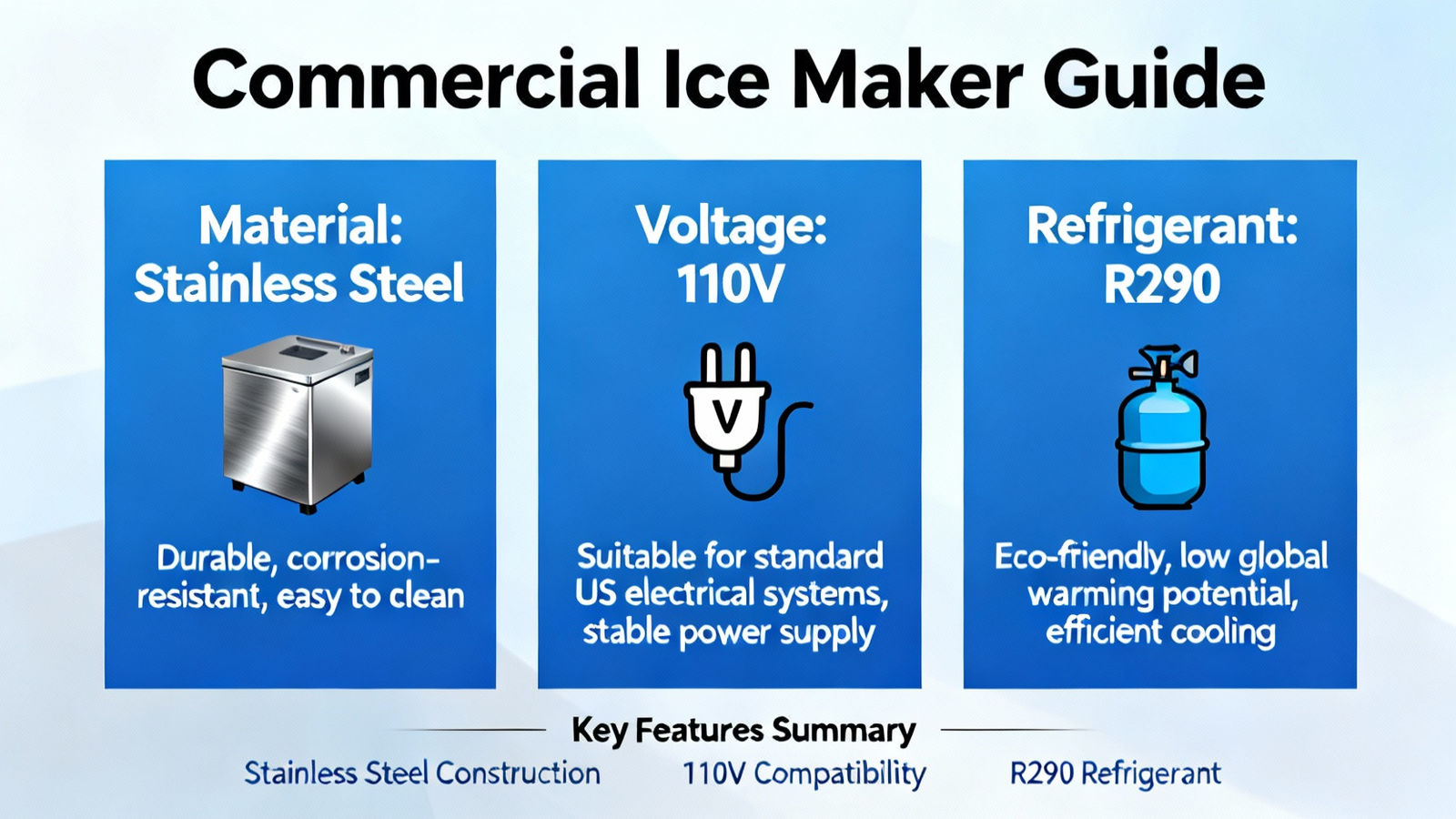

Commercial Ice Maker Guide: Stainless Steel, 110V, and R290

For restaurants, bars, and hotels, a reliable ice maker is the backbone of service. This guide delves into the heavy-duty commercial ice maker, focusing on its durable stainless steel construction, proper installation for 110V 60Hz operation, and critical safety and maintenance protocols. Understanding these elements is key to maximizing performance and longevity in demanding environments.

Engineering for Endurance: Stainless Steel and R290 Refrigerant

The hallmark of any commercial-grade appliance is durability. This ice maker’s stainless steel construction is not just for aesthetics; it provides superior corrosion resistance, essential for withstanding constant moisture and rigorous cleaning with sanitizers. This aligns with industry standards where stainless steel is preferred for food contact surfaces due to its non-porous nature and ease of maintenance, as noted in discussions on food service equipment longevity.

Equally important is the use of environmentally friendly R290 refrigerant. R290, or propane, is a natural hydrocarbon with a very low Global Warming Potential (GWP). Its adoption is a significant shift in the commercial refrigeration industry toward more sustainable practices. As highlighted on Wikipedia, R290 is an efficient refrigerant with excellent thermodynamic properties, but its flammability requires precise engineering in the system design, which is addressed by the unit’s Safety Protection Type I classification.

Installation Essentials: Space, Power, and Water Supply

Correct installation is non-negotiable for optimal function and safety. The requirement for at least 5.9 inches of clearance on all sides is critical for airflow, allowing the condenser to dissipate heat efficiently. Ignoring this can lead to overheating, increased energy consumption, and premature failure.

Power and water specifications are equally precise. The 780W, 110V 60Hz operation is standard for North American commercial kitchens, but the warning against using an extension cord is vital. As often reiterated in electrician forums on Reddit, high-wattage appliances like this commercial ice maker require a dedicated outlet to prevent cord overheating and fire risk. The water supply must be potable and within the 14.5-58 psi pressure range. Pressure outside this window can damage internal valves, underscoring the need for a changeover valve as specified.

Operational Safety and Initial Startup Protocol

Safety extends beyond installation. The explicit warnings to keep the unit away from flammable materials and not to use it outdoors address common misconceptions. Furthermore, using only water prevents damage to the ice-making mechanism and potential contamination.

The most critical step is the 24-hour settling period after delivery. This allows the compressor oil, which may have migrated during transit, to settle back. Running the unit immediately can cause severe compressor damage. A similar protocol is recommended for various refrigeration appliances, as users on subreddits like r/Appliances advise, to ensure refrigerant stability before initial startup.

Maintenance and Environmental Considerations for Peak Performance

Long-term reliability hinges on proper maintenance and understanding environmental impacts. The gravity-fed drainage system requires the drain pipe outlet to be lower than the machine’s outlet, ensuring meltwater and wastewater are effectively removed to prevent internal stagnation and microbial growth.

Ambient temperature directly affects efficiency. The unit’s compatibility with climate types SN, N, ST means it’s designed for varied environments, but performance will vary. As noted in a 2023 discussion on commercial kitchen equipment, ice production times can increase significantly in hotter ambient temperatures because the condenser works harder. Placing the unit away from direct sunlight and heat sources like stoves, as instructed, mitigates this effect and maintains consistent ice making capacity, such as that offered by a high-output 750 lbs./24h capacity model.

In summary, integrating a heavy-duty commercial ice maker into your business is an investment in operational efficiency. Its durable stainless steel construction and advanced R290 refrigerant system are engineered for sustainability and long-term service. However, this durability is fully realized only through strict adherence to installation guidelines—including proper clearance, dedicated 110V 60Hz power, and regulated water pressure—and rigorous safety protocols, most importantly the mandatory 24-hour settling period. Furthermore, acknowledging how environmental temperature influences production and ensuring correct drainage setup are ongoing considerations for peak performance. By viewing this appliance as a system where engineering, correct installation, and informed operation intersect, businesses can ensure their commercial stainless steel ice maker becomes a reliable asset, meeting high-demand needs in restaurants, bars, and hotels for years to come.