Commercial Ice Maker Guide: 500 lb/24h Specs, Setup, Safety

For restaurants, bars, and hotels, a reliable ice maker is a backbone of daily operations. This guide delves into the critical specifications, installation requirements, and safety protocols for a heavy-duty 500 lb./24h capacity commercial ice maker. Understanding these details ensures optimal performance, longevity, and safety for your business, turning a significant equipment investment into a seamless part of your service.

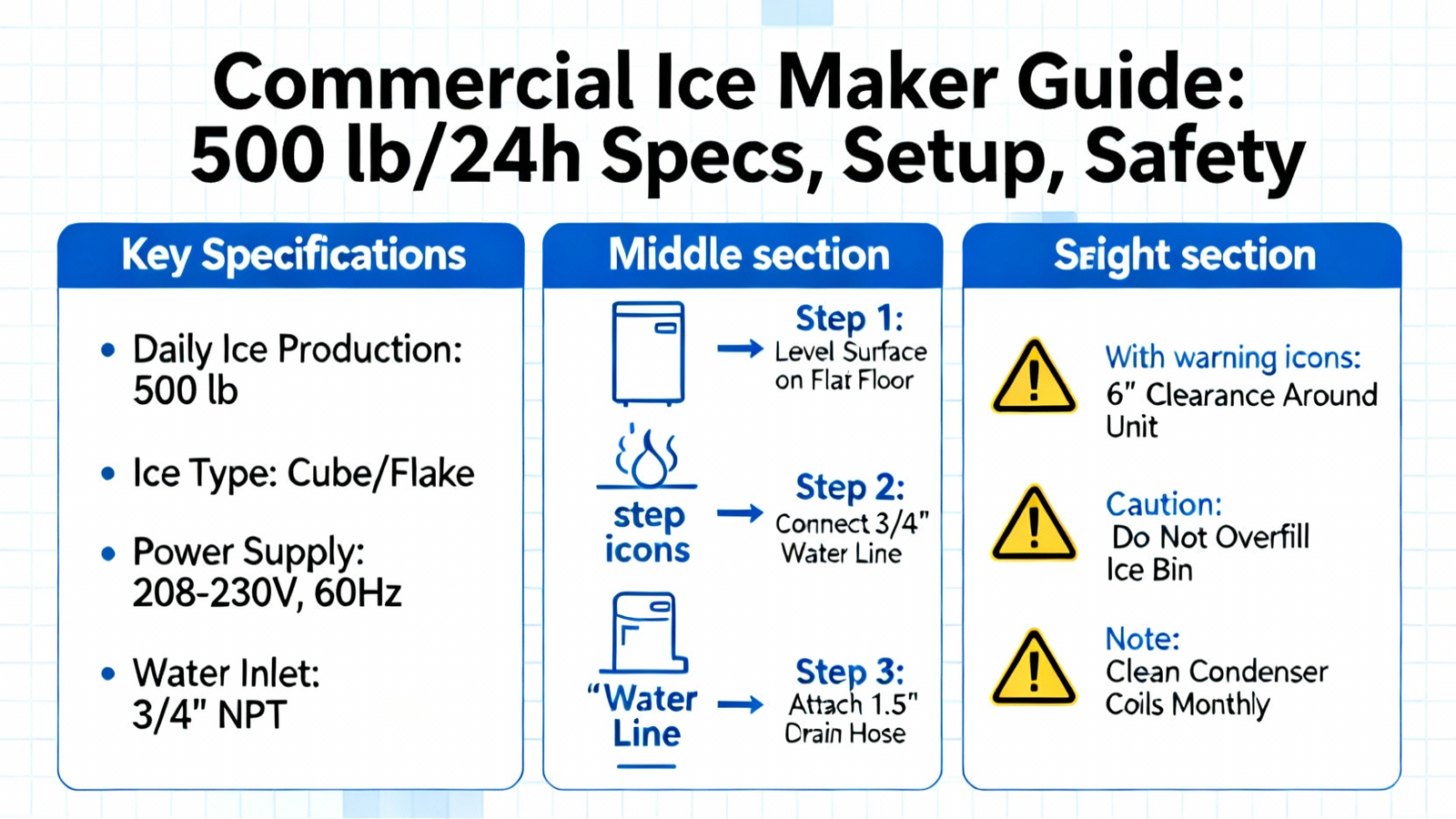

Engineering for Endurance: Core Specifications & Build

This commercial ice maker is engineered for demanding environments. Its durable stainless steel construction resists corrosion and is easy to clean, meeting the rigorous hygiene standards of food service. Operating on standard 110V 60Hz power with 780W draw, it’s designed for compatibility with U.S. electrical systems. A key feature is its use of R290 (propane) refrigerant, an environmentally friendly option with a low Global Warming Potential (GWP). As noted on Wikipedia, hydrocarbons like R290 are “being increasingly used due to their excellent thermodynamic properties and low environmental impact,” though they are flammable and require proper handling. Its compatibility with climate types SN, N, and ST ensures reliable ice production across varied temperate environments common in the United States.

Pre-Installation: Site Requirements & Safety First

Proper setup is non-negotiable for safety and efficiency. The unit requires a drinking water supply with a pressure between 14.5-58 psi; outside this range, a pressure changeover valve is mandatory. Critical clearance of at least 5.9 inches (15 cm) on all sides is needed for airflow and heat dissipation, a point often emphasized by professionals in forums like r/KitchenConfidential to prevent overheating. Safety mandates include avoiding extension cords, keeping the unit away from flammable materials and heat sources like stoves, and prohibiting outdoor use. The included three-prong plug and 70″ cord are part of its Safety Protection Type I design for grounded protection.

Initial Startup & Operational Best Practices

Upon delivery, a specific protocol must be followed. The unit must remain upright for 24 hours before initial plug-in to allow compressor oil to settle, followed by an additional hour for the refrigerant to stabilize—bypassing this can cause immediate compressor failure. A gravity-fed drain pipe must be connected before operation, as meltwater is continuously discharged; its outlet must be lower than the ice maker’s port. Users should only use water, as other liquids can damage the system and create health hazards. It’s also important to understand that ambient temperature directly influences ice production cycles, with hotter environments potentially slowing output.

Long-Term Performance & Maintenance Insights

To ensure the commercial stainless steel ice maker reaches its potential of 500 lbs./24h, consistent maintenance is key. Regular cleaning of the water distribution system and air filter prevents scale and debris buildup, which are common causes of downtime. As discussed by users in industry threads, such as a r/refrigeration post on preventative maintenance, establishing a scheduled service plan for components like the water inlet valve and condenser is crucial for a heavy-duty commercial ice maker. Monitoring water quality can also prevent mineral accumulation that strains the R290 refrigeration system, safeguarding your investment and ensuring a consistent ice supply for your restaurant, bar, or hotel.

In summary, maximizing the return on your 23.2 in. 500 lbs./24h Capacity Commercial Stainless Steel Ice Maker hinges on a triad of careful installation, strict adherence to safety, and proactive maintenance. From ensuring proper water pressure and critical clearances to observing the vital 24-hour settling period, the initial setup lays the foundation for reliable service. Operational vigilance—such as using only potable water, maintaining the drain line, and keeping the unit in a climate-controlled environment—preserves the machine’s integrity and output. Furthermore, embracing a regimen of scheduled cleaning, as advocated by industry professionals on platforms like Reddit, mitigates the common pitfalls that lead to breakdowns. By treating this durable appliance as the precision-engineered asset it is, businesses in the United States can secure a dependable, efficient, and safe ice production system that supports daily operations seamlessly for years to come.