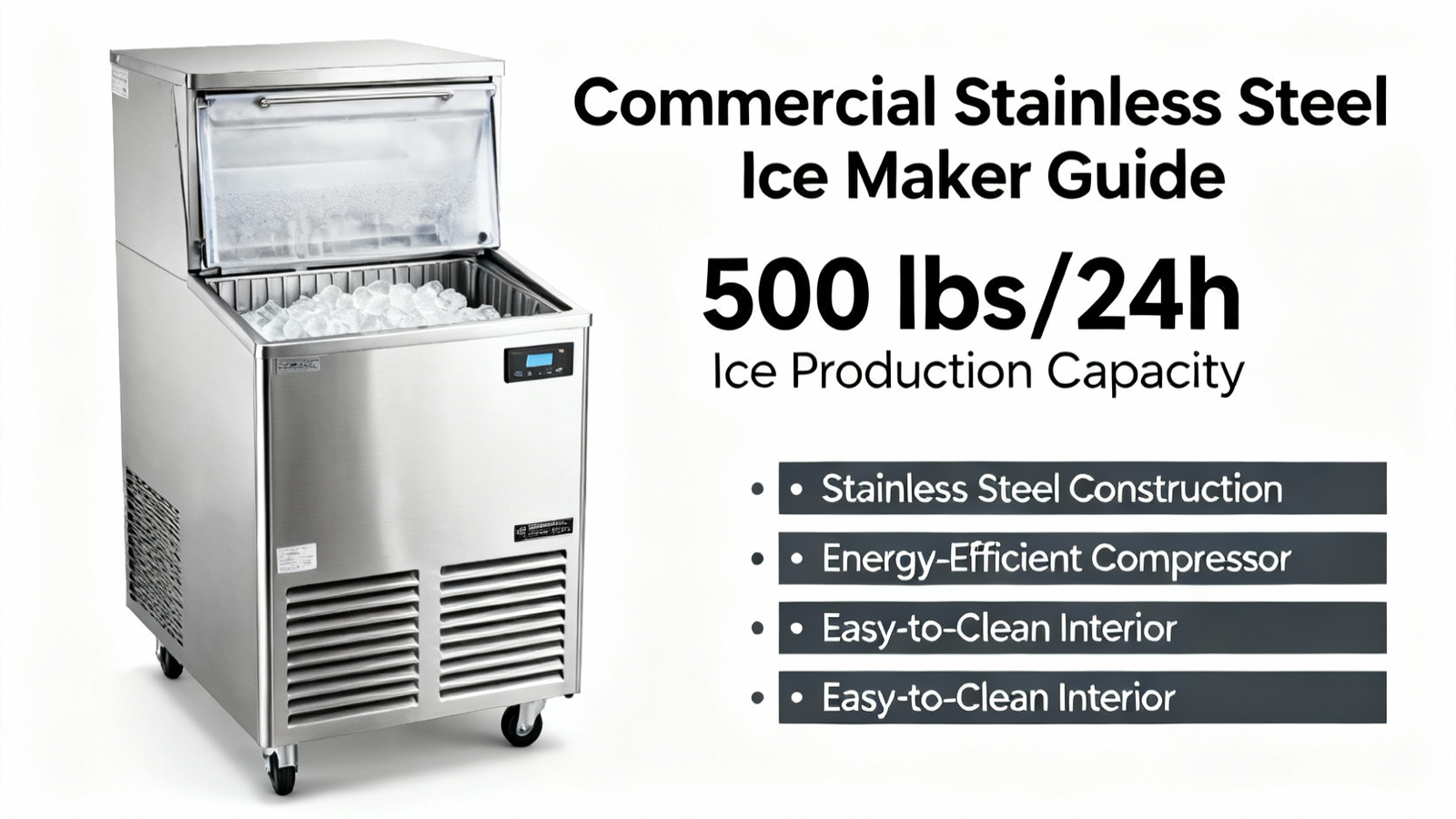

Commercial Stainless Steel Ice Maker, 500 lbs/24h Guide

For restaurants, bars, and hotels, a reliable ice maker is the backbone of service. This guide delves into the 23.2 in. 500 lbs./24h Capacity Commercial Stainless Steel Ice Maker, exploring its heavy-duty construction, critical installation requirements, and essential safety protocols to ensure optimal performance and longevity in a demanding commercial environment.

Engineering for Endurance: Stainless Steel and R290 Refrigerant

At the core of this unit is its durable stainless steel construction, a material chosen for its resistance to corrosion, ease of cleaning, and ability to withstand the high humidity and frequent cleaning cycles of a commercial kitchen. This aligns with industry standards where stainless steel is preferred for food service equipment due to its sanitary properties. Furthermore, the machine utilizes environmentally friendly R290 refrigerant, a propane-based solution with a low Global Warming Potential (GWP). As noted in discussions on refrigerant trends, R290 is gaining favor as an eco-friendly alternative to traditional HFCs, though it requires specific safety considerations due to its flammability, which the unit’s design accounts for with its Safety Protection Type I classification.

Its compatibility with climate types SN, N, and ST ensures reliable operation in varied ambient temperatures, a critical factor for kitchens with fluctuating conditions. The 110V/60Hz operation and 780W power draw make it suitable for standard US commercial outlets, offering substantial ice production—500 lbs. per 24 hours—without requiring specialized electrical infrastructure.

Pre-Installation: Space, Settling, and Water Supply

Proper installation is paramount. Upon delivery, the unit must be left upright for 24 hours before initial use. This allows the compressor oil, which may have shifted during transit, to settle, preventing potential damage—a critical step emphasized in user manuals and service forums. Placement requires at least 5.9 inches (15 cm) of clearance on all sides for adequate airflow, ensuring the condenser can expel heat efficiently.

The water connection is not a mere suggestion; it requires a drinking water supply with a pressure between 14.5 and 58 psi. Pressure outside this range can lead to poor ice formation or system damage, necessitating a pressure changeover valve. Additionally, a gravity-fed drain line must be installed, with its outlet lower than the machine’s port, to handle continuous wastewater discharge from the melting ice in the storage bin.

Critical Safety and Operational Protocols

Adherence to safety guidelines protects both personnel and property. Key mandates include:

- Never using an extension cord, as the 70-inch provided cord is rated for the 780W load. An undersized cord can overheat, creating a fire risk—a point frequently stressed in electrical safety guidelines.

- Keeping the unit away from flammable materials and heat sources like stoves or direct sunlight. Ambient temperature directly influences ice production cycles, as noted in the specifications.

- Using only water in the unit. Introducing other liquids can damage the internal components and contaminate the ice.

- Ensuring the three-prong plug is connected to a properly grounded outlet, which is essential for safe operation of any commercial appliance with a metal chassis.

Maximizing Longevity and Performance

To ensure the commercial stainless steel ice maker delivers its promised 500-lb. daily capacity for years, operational mindfulness is key. The prohibition against outdoor use is due to environmental contaminants, temperature extremes, and weather exposure that the unit is not sealed against. Regular cleaning and descaling, as per the manufacturer’s schedule, will prevent mineral buildup that hampers efficiency. Recognizing that ice production time varies with room temperature helps set accurate expectations during peak service. Ultimately, this machine is engineered for high-volume, indoor commercial settings where its stainless steel durability and proper installation converge to create a dependable ice supply.

In conclusion, the 23.2 in. 500 lbs./24h Commercial Stainless Steel Ice Maker represents a significant investment in operational efficiency for any food service business. Its robust construction with stainless steel and modern R290 refrigerant provides a foundation for reliability and environmental responsibility. However, its performance is wholly dependent on meticulous adherence to installation and safety protocols—from the mandatory 24-hour settling period and precise water pressure requirements to the critical prohibitions on extension cords and outdoor use. By understanding the engineering rationale behind these requirements, such as the need for proper airflow clearance and a grounded outlet, operators can fully leverage the machine’s high-capacity output. When installed and maintained correctly, this heavy-duty ice maker transitions from a simple appliance to a core component of daily service, ensuring a consistent supply of ice that keeps beverages cold and operations flowing smoothly in restaurants, bars, and hotels across the United States.