Commercial Ice Maker Guide: 500 lb. Capacity Specs & Safety

For restaurants, bars, and hotels, a reliable ice maker is a cornerstone of daily operations. This guide delves into the critical specifications, installation requirements, and safety protocols for a heavy-duty 500 lb./24h capacity commercial ice maker. Understanding these details is essential for maximizing performance, ensuring longevity, and maintaining the highest standards of operational safety in your business.

Engineering for Commercial Endurance

Built with durable stainless steel construction, this ice maker is designed for the rigors of high-volume environments. Its 110V/60Hz operation and 780W power draw make it suitable for standard commercial kitchens in the United States, while the use of environmentally friendly R290 (propane) refrigerant reflects modern environmental standards. R290 is recognized for its low global warming potential, as noted in refrigerant comparisons on Wikipedia. Weighing approximately 145.51 lb. and measuring 26.4” x 23.2” x 61.4”, its footprint is designed for efficiency. Compatibility with climate types SN, N, and ST (Subnormal, Normal, and Subtropical) ensures reliable performance across varied regional environments, a critical factor for nationwide operations.

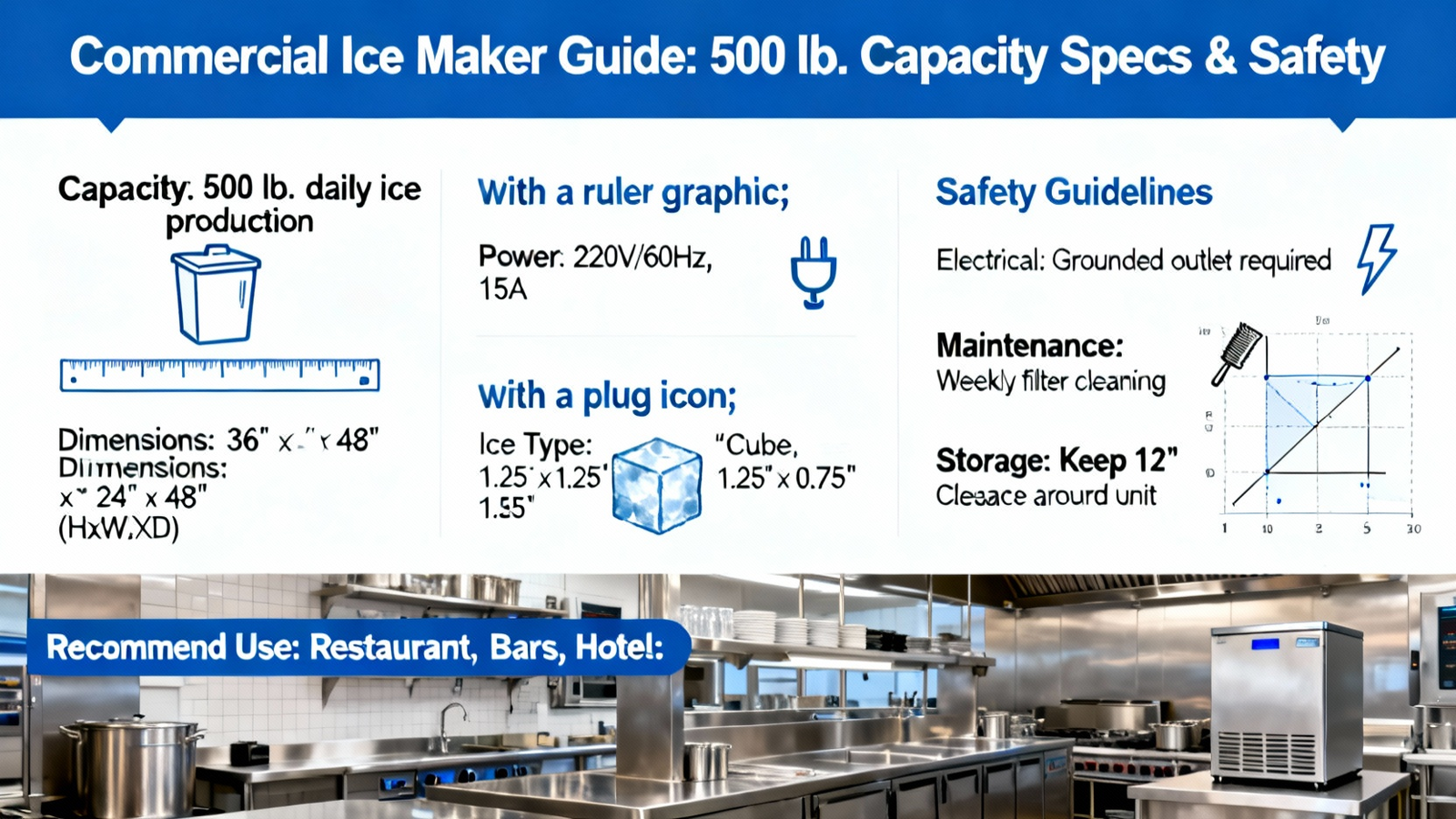

Critical Installation and Setup Protocols

Proper installation is non-negotiable for safety and efficiency. The unit requires a direct connection to a potable water supply with a pressure between 14.5 and 58 psi; outside this range, a pressure changeover valve is mandatory. As discussed in industry threads on Reddit, such as a kitchen professional’s query about water lines, correct water pressure is vital to prevent mechanical issues. The machine must be positioned with at least 5.9 inches of clearance on all sides for airflow and must be placed on a level surface. Crucially, upon delivery, the unit must remain upright for 24 hours to let the compressor oil settle, as advised for any refrigeration equipment, before its initial one-hour refrigerant settling period prior to startup.

Operational Safety and Best Practices

Adhering to safety guidelines protects both personnel and equipment. The ice maker comes with a three-prong plug and a 70-inch cord; using an extension cord is strongly discouraged due to overheating and fire risks, a common warning echoed in appliance manuals and forums. It must be kept away from flammable materials, direct sunlight, and heat sources like stoves. Importantly, it is designed for indoor use only. Only clean, potable water should be used to make ice, as other liquids can damage the system and create health hazards. The internal wastewater is discharged by gravity, so the drain pipe outlet must be lower than the machine’s port to ensure proper flow and prevent backups.

Maintenance and Performance Considerations

Long-term reliability hinges on understanding the machine’s operation. The surrounding ambient temperature directly influences ice production cycles, with hotter environments potentially slowing output. Regular cleaning and sanitizing, as per the manufacturer’s schedule, are imperative to prevent scale and biological growth, topics frequently emphasized by food safety authorities. The 23.2 in. 500 lbs./24h Capacity Commercial Stainless Steel Ice Maker is built for heavy-duty cycles, but its lifespan is extended by proactive maintenance. Always consult the official manual for specific cleaning agents and procedures to avoid damaging the stainless steel or internal components.

Conclusion

Investing in a commercial ice maker like the stainless steel 500 lb./24h capacity unit is a significant decision for any foodservice business. Its durable construction, compatible climate design, and use of R290 refrigerant position it as a modern, efficient workhorse. However, its value is fully realized only through meticulous attention to installation prerequisites—such as proper water pressure, clearance, and the mandatory 24-hour settling period—and strict adherence to operational safety rules, including indoor use only and avoiding extension cords. By integrating these practices with a consistent maintenance routine, operators can ensure this critical asset delivers reliable, sanitary ice production day in and day out, supporting seamless service and contributing to the overall success and safety of the establishment. Ultimately, the performance of your commercial ice maker is a direct result of how well it is installed, operated, and cared for.