Commercial Ice Maker Guide: Specs, Setup, and Safety

The Ultimate Guide to Heavy-Duty Commercial Ice Makers: Performance, Setup, and Safety

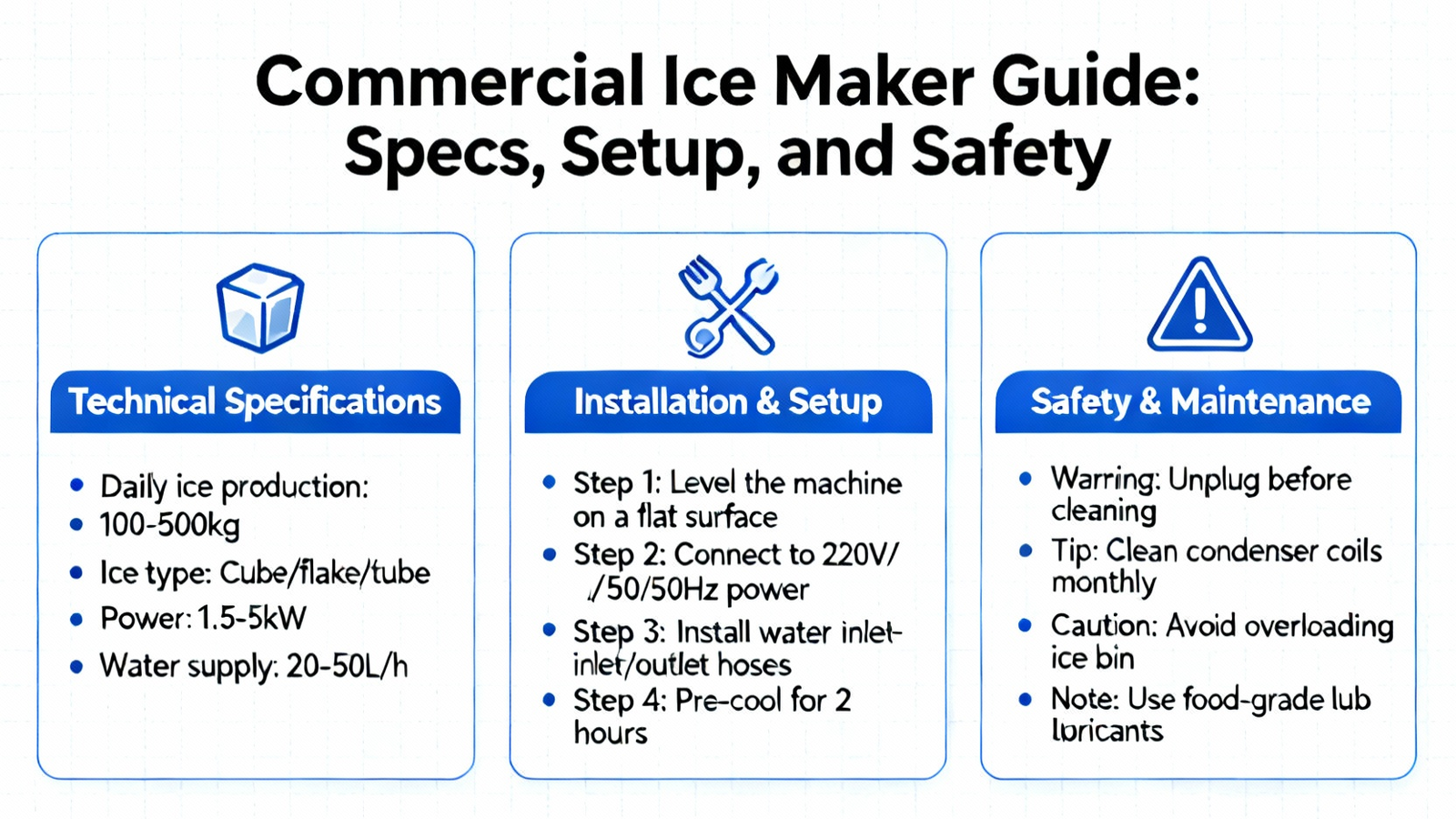

Selecting and installing a commercial ice maker is a critical decision for any foodservice business. This guide delves into the specifications of a robust, stainless steel unit designed for 110V operation, exploring its technical advantages, correct installation procedures, and essential safety protocols. Understanding these elements is key to ensuring reliable ice production, equipment longevity, and operational safety in demanding environments like restaurants, bars, and hotels.

Engineering for Commercial Endurance

At the core of a reliable commercial ice maker is its construction and components. The highlighted unit features a durable stainless steel exterior, which, as noted in discussions on commercial kitchen durability, is preferred for its corrosion resistance and ease of cleaning (Reddit, r/KitchenConfidential threads, 2023). Its operation on standard 110V/60Hz power at 780W makes it accessible for most US commercial settings without requiring specialized electrical work. A significant modern feature is the use of R290 (propane) refrigerant. According to Wikipedia, R290 has a “negligible ozone depletion potential and very low global warming potential compared to traditional hydrofluorocarbon refrigerants”, making it an environmentally progressive choice. Compatibility with climate types SN, N, and ST ensures stable performance across varied US regional temperatures.

Critical Pre-Installation and Placement Guidelines

Proper setup is non-negotiable for performance and warranty. Key steps include:

- Site Preparation: Allow a minimum 5.9 inches (15 cm) of clearance on all sides for adequate airflow and heat dissipation, a point often emphasized by HVAC professionals on forums like r/Appliances.

- Water Supply Requirements: The unit requires a potable drinking water connection with pressure strictly between 14.5 and 58 PSI. Pressure outside this range necessitates a changeover valve to prevent mechanical failure.

- Initial Startup Protocol: After delivery, the unit must remain upright for 24 hours to let the compressor oil settle. A further one-hour wait for the R290 refrigerant to stabilize is crucial before first power-on, ensuring system integrity.

- Drainage is Mandatory: A gravity-fed drain pipe, with its outlet lower than the ice maker’s drain port, must be connected to handle meltwater and internal discharge, preventing water damage and sanitation issues.

Operational Safety and Maintenance Imperatives

Safety in commercial equipment involves adherence to manufacturer guidelines and common sense. This model is a Safety Protection Type I appliance, indicating it is designed for stationary use with a permanently connected power source. Critical rules include:

- Power Safety: The included three-prong plug and 70-inch cord should connect directly to a grounded outlet. Extension cords are not recommended as they can overheat, a fire risk corroborated by the U.S. Consumer Product Safety Commission and discussed in safety-focused subreddits.

- Environmental Controls: Keep the unit away from direct sunlight, stoves, or radiators. Ambient temperature directly affects ice production cycles, and excess heat forces the compressor to overwork.

- Strictly Water Only: Using any liquid other than water to make ice can damage the machine, contaminate the ice, and void the warranty.

- Indoor Use Only: The unit is not rated for outdoor use, where environmental factors and temperature fluctuations would compromise its operation and safety.

Conclusion: Investing in Reliable Ice Production

Implementing a heavy-duty commercial ice maker is an investment in the daily workflow and customer satisfaction of a foodservice business. From its stainless steel construction and eco-friendly R290 refrigerant to its specific voltage and climate compatibility, each specification is designed for demanding, high-volume use. However, the engineering alone cannot guarantee success. As outlined, rigorous adherence to installation guidelines—proper clearance, correct water pressure, mandatory drainage, and the vital 24-hour settling period—is what transitions the machine from a piece of equipment to a reliable asset. Furthermore, unwavering commitment to operational safety, including direct power connection, appropriate placement away from heat, and exclusive use of water, protects both your staff and your investment. By understanding and executing on these technical and procedural details, businesses can ensure their commercial ice maker delivers consistent, clean ice safely and efficiently for years to come, forming an indispensable part of a professional kitchen or bar’s infrastructure.

This guide really clarifies what specs to prioritize when choosing a commercial ice maker for my restaurant.

\}}

This guide really clarifies what specs to prioritize when choosing a commercial ice maker for my restaurant.

\}}

This guide really clarifies what specs to prioritize when choosing a commercial ice maker for my restaurant.

\}}

This guide really clarifies what specs to prioritize when choosing a commercial ice maker for my restaurant.

\}}