Commercial Ice Maker Guide: Features, Safety & Setup

Heavy-Duty Commercial Ice Maker: The Ultimate Guide to Features, Safety & Setup

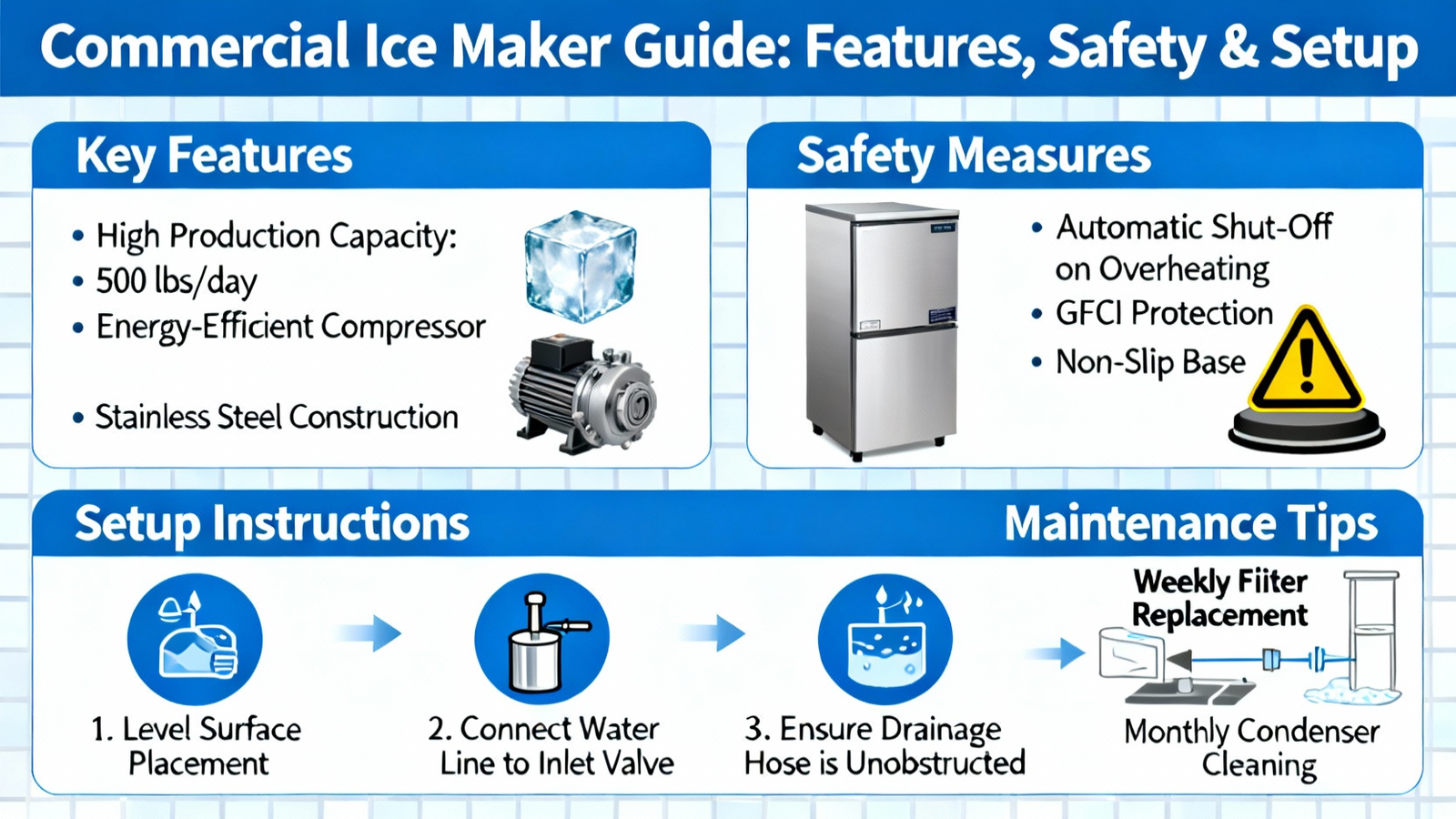

Selecting the right commercial ice maker is crucial for any foodservice operation. This guide delves into the specifics of a robust, stainless steel unit designed for high-volume environments, covering its key features, essential installation requirements, and critical safety protocols to ensure optimal performance and longevity.

Engineering for High-Volume Demands

Built for restaurants, bars, and hotels, a true heavy-duty ice maker like the 23.23 in. 750 lbs./24h Capacity Commercial Stainless Steel Ice Maker is defined by durable construction and powerful output. The use of 304-grade stainless steel, a standard in commercial kitchens for its corrosion resistance and ease of cleaning, ensures longevity in demanding environments. The unit’s compatibility with climate types SN, N, and ST (Subnormal, Normal, and Subtropical) means it can reliably operate in varied ambient temperatures, a critical factor for back-of-house spaces that may not be perfectly climate-controlled. This adaptability is backed by the use of R290 (propane) refrigerant, an environmentally friendly hydrocarbon with a low Global Warming Potential (GWP), as noted in discussions on refrigerant trends within the industry.

Critical Pre-Installation and Setup Protocol

Proper setup is non-negotiable for performance and warranty. Two of the most vital steps are often overlooked. First, after transportation, the compressor oil must settle; thus, letting the unit stand upright for 24 hours before initial power-up is mandatory to prevent severe damage. Second, a dedicated drinking water line with correct pressure (14.5-58 psi) is required. As highlighted in a Reddit discussion from August 2023, improper water pressure or untreated hard water is a leading cause of scale buildup and premature failure in commercial ice makers. Furthermore, the gravity-fed drain line must be installed with a downward slope, as the unit continuously purges wastewater during the freeze cycle.

Operational Safety and Environmental Guidelines

Safety in commercial equipment involves both electrical and spatial planning. This ice maker’s 780W draw on a standard 110V circuit requires a dedicated outlet; using an extension cord is a documented fire hazard due to potential overheating. The unit must have at least 6 inches of clearance on all sides for adequate airflow, preventing compressor overload. It should be kept away from heat sources like stoves and direct sunlight, as ambient temperature directly impacts freeze cycles and efficiency. Importantly, these units are designed for indoor, well-ventilated use only. Using them outdoors exposes electrical components to moisture and can cause the refrigerant system to operate outside its engineered climate range, leading to failure.

Maintenance and Long-Term Performance

Consistent maintenance stems from proper daily use. Only potable water should be used, as sugars or additives in other liquids will damage the evaporator plate and water distribution system. Regular cleaning with approved sanitizers is essential to prevent biofilm and scale, which harbor bacteria like Legionella and reduce efficiency. According to Wikipedia’s entry on ice machines, regular descaling and sanitizing are critical public health measures in commercial settings. The machine’s performance is also tied to its environment; a hotter room temperature will increase ice production time, so placing it in a cool, shaded location is an operational best practice.

Conclusion: Investing in Reliable Ice Production

In summary, a commercial ice maker is a significant investment that demands careful consideration of its technical specifications, installation environment, and operational care. The highlighted model, with its stainless steel build, high-capacity output, and environmentally conscious R290 refrigerant, is engineered for the rigors of daily service in establishments like restaurants and hotels. However, its durability is contingent upon strict adherence to setup protocols—including proper water line connection, mandatory settling time, and correct drainage—and ongoing safety practices, such as avoiding extension cords and ensuring adequate ventilation. As supported by industry discussions and maintenance guidelines, the longevity and hygienic operation of any commercial ice maker are directly proportional to the user’s commitment to these procedures. By following this comprehensive guide, operators can ensure their equipment delivers reliable, clean ice, supporting seamless service and safeguarding their investment for years to come.

This guide really helped clarify the key features to look for in a commercial ice maker for our busy kitchen.

\}}

This guide really helped clarify the key features to look for in a commercial ice maker for our busy kitchen.

\}}

This guide really helped clarify the key features to look for in a commercial ice maker for our busy kitchen.

\}}

This guide really helped clarify the key features to look for in a commercial ice maker for our busy kitchen.

\}}