Heavy-Duty Commercial Ice Maker Guide: Features & Setup

The Ultimate Guide to Heavy-Duty Commercial Ice Makers

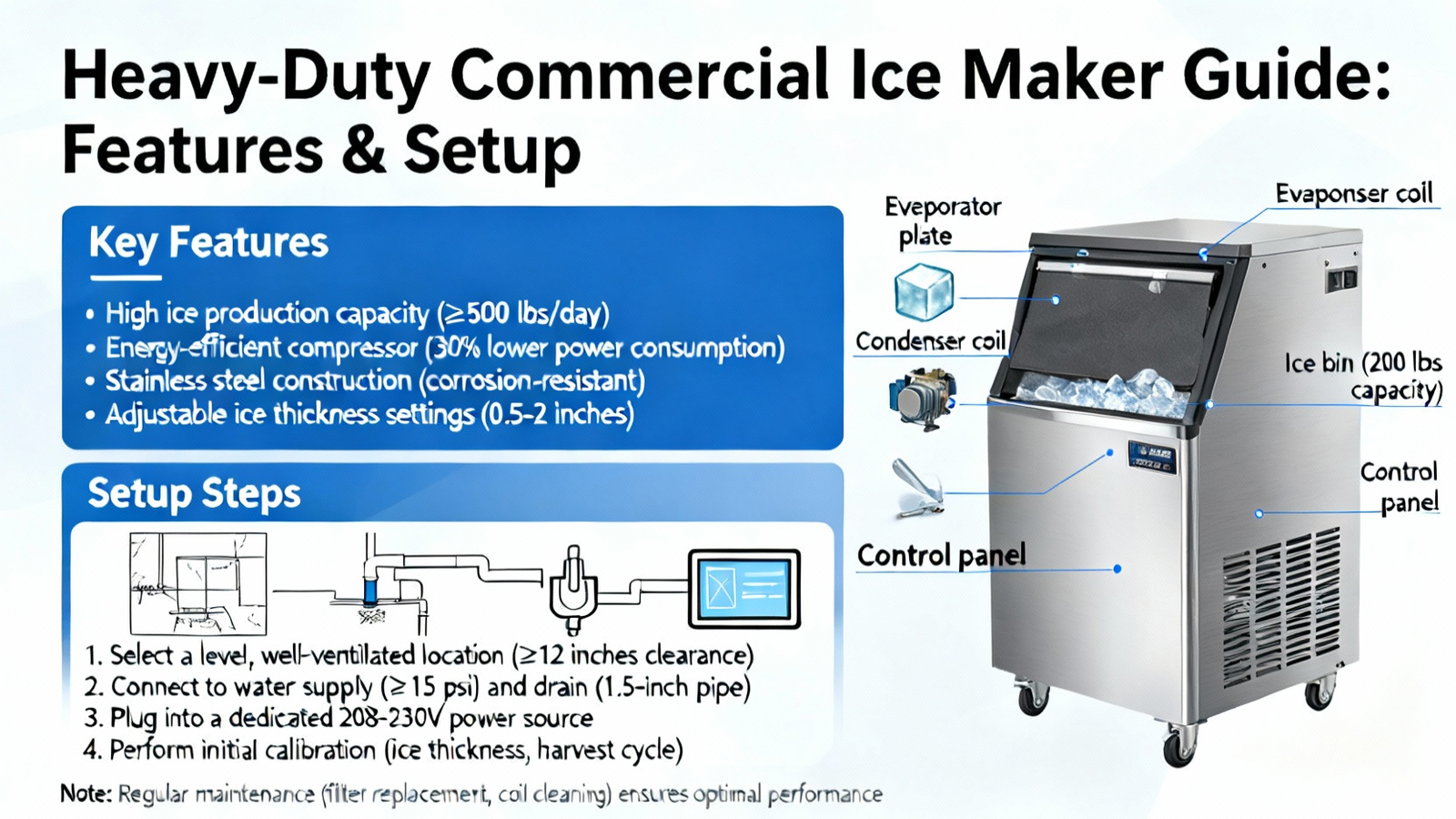

Selecting and installing a commercial ice maker is a critical decision for any food service business. This guide delves into the robust features of a professional-grade, stainless steel unit, explores its environmental and operational specs, and provides a detailed, safety-focused setup checklist to ensure peak performance and longevity for your investment.

Engineering for Endurance: Build and Core Specifications

At the heart of a reliable commercial ice maker is its construction. Units built with durable stainless steel are the industry standard, prized for their corrosion resistance, ease of cleaning, and longevity in high-moisture environments. This material is so pivotal that Wikipedia notes its use in food service is driven by the need to “prevent iron contamination and to impart corrosion resistance,” essential for maintaining hygiene and equipment life. A model like the heavy-duty commercial ice maker leverages this material for a cabinet designed to withstand the rigors of a bustling kitchen or bar. With a net weight of approximately 145.51 lb and dimensions of 26.4 × 23.2 × 61.4 in, its substantial build indicates a high-capacity, stationary appliance meant for continuous use in restaurants, hotels, and catering.

Power, Climate, and Environmental Considerations

Operational compatibility is non-negotiable. A unit designed for 110V 60Hz operation with 780W power draw is configured for standard North American electrical systems, offering easier integration without specialized wiring. The use of R290 (propane) refrigerant is a significant modern advancement. As a natural refrigerant with a very low Global Warming Potential (GWP), R290 is increasingly favored for its environmental benefits over traditional HFCs. Furthermore, its Climate Class SN, N, ST compatibility means the machine is engineered to perform reliably in a wide range of ambient temperatures, from +10°C to +38°C (50°F to 100°F), ensuring consistent ice production in varied kitchen environments, a point often emphasized in industry discussions on equipment reliability.

Critical Installation and Safety Protocols

Proper installation is paramount for safety and efficiency. The provided notes are not mere suggestions but essential requirements. Key steps include:

- Water Supply & Drainage: A direct connection to drinking water is mandatory for ice quality and machine health. Water pressure must be regulated to 14.5-58 psi, and a gravity drain pipe, installed lower than the machine’s outlet, is required to handle meltwater, as the unit is not a storage freezer.

- Site Preparation & Ventilation: Leaving a minimum 15 cm (5.9 in) clearance on all sides is crucial for airflow and heat exchange, directly impacting the compressor’s lifespan and ice-making time. Placing the unit away from heat sources and direct sunlight prevents overworking the system.

- Electrical and Initial Startup Safety: The included three-prong plug requires a proper grounded outlet. Extension cords are prohibited due to the high, continuous power draw, which can cause overheating and fire risk—a hazard frequently cited in safety forums. After delivery, the unit must stand upright for 24 hours to let compressor oil settle, a critical step to prevent mechanical failure upon startup.

Optimizing for Long-Term Performance and Safety

Beyond installation, long-term care involves understanding operational nuances. Users must only use water, as other liquids can damage the evaporator and contaminate ice. The machine is for indoor use only; outdoor exposure to elements and temperature extremes can cause malfunctions and safety issues with the electrical components. As highlighted in a Reddit discussion on commercial ice machine maintenance, regular cleaning and adherence to manufacturer setup guidelines are the most effective ways to ensure food safety and machine reliability. Recognizing that ice production time varies with ambient temperature helps set accurate expectations during peak service hours.

Conclusion: A Strategic Investment for Your Business

In summary, a commercial ice maker like the featured stainless steel ice maker represents a significant investment in your operation’s infrastructure. Its durable construction, climate-adaptive design, and use of eco-friendly R290 refrigerant position it as a modern, responsible choice. However, its engineered potential is only realized through meticulous installation and operation. By strictly following the protocols for spacing, electrical connection, water supply, drainage, and initial startup, you safeguard both the equipment and your premises. This diligence ensures the machine delivers the consistent, high-volume ice production that restaurants, bars, and hotels depend on. Ultimately, treating your commercial ice maker as a core component of your kitchen’s ecosystem—with needs for proper space, utilities, and care—is the key to unlocking years of reliable service, supporting seamless customer experiences and protecting your bottom line.

This guide really helped me understand the key features to look for in a heavy-duty commercial ice maker for our new restaurant.

\}}

This guide really helped me understand the key features to look for in a heavy-duty commercial ice maker for our new restaurant.

\}}

This guide really helped me understand the key features to look for in a heavy-duty commercial ice maker.

\}}

This guide really helped me understand the key features to look for in a heavy-duty commercial ice maker.

\}}

This guide really helped me understand the key features to look for in a heavy-duty commercial ice maker.

\}}

This guide really helped me understand the key features to look for in a heavy-duty commercial ice maker.

\}}

This guide really helped me understand the key features to look for in a heavy-duty commercial ice maker.

\}}